News & Events

2022

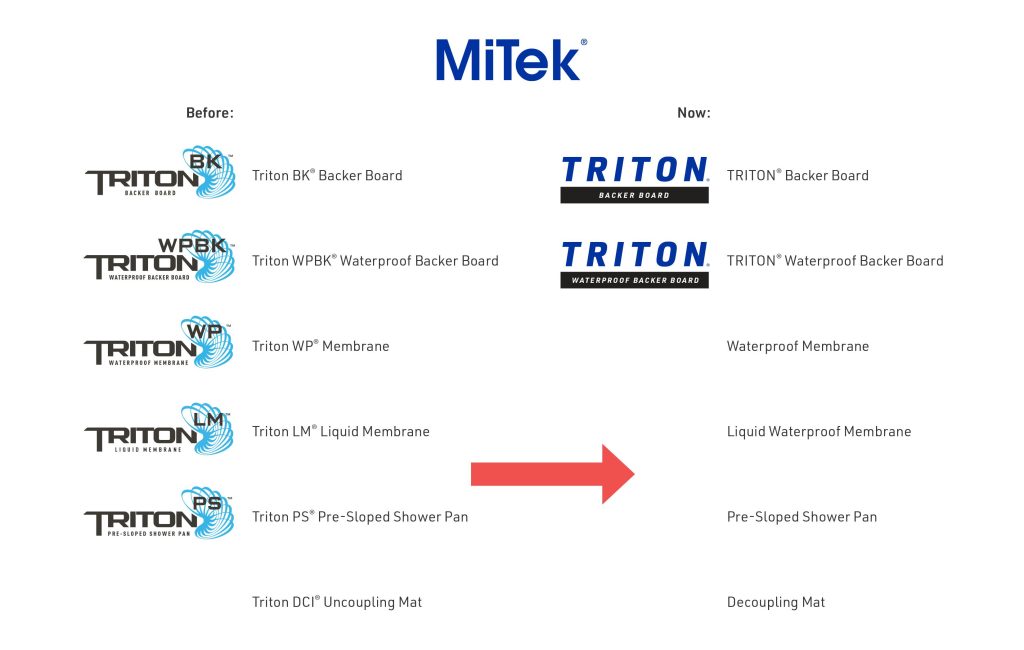

Today MiTek announces the realignment of the Triton brand name from a branded product line name (Triton® Watertight System) to a branded technology name (TRITON® Technology) that aligns with its purpose to enable better building. The TRITON brand name is used for MiTek’s solutions, where the MgO-based nanomolecular veneer cement technology is the primary material used to make the product. This brand change includes updates to logos and names only.

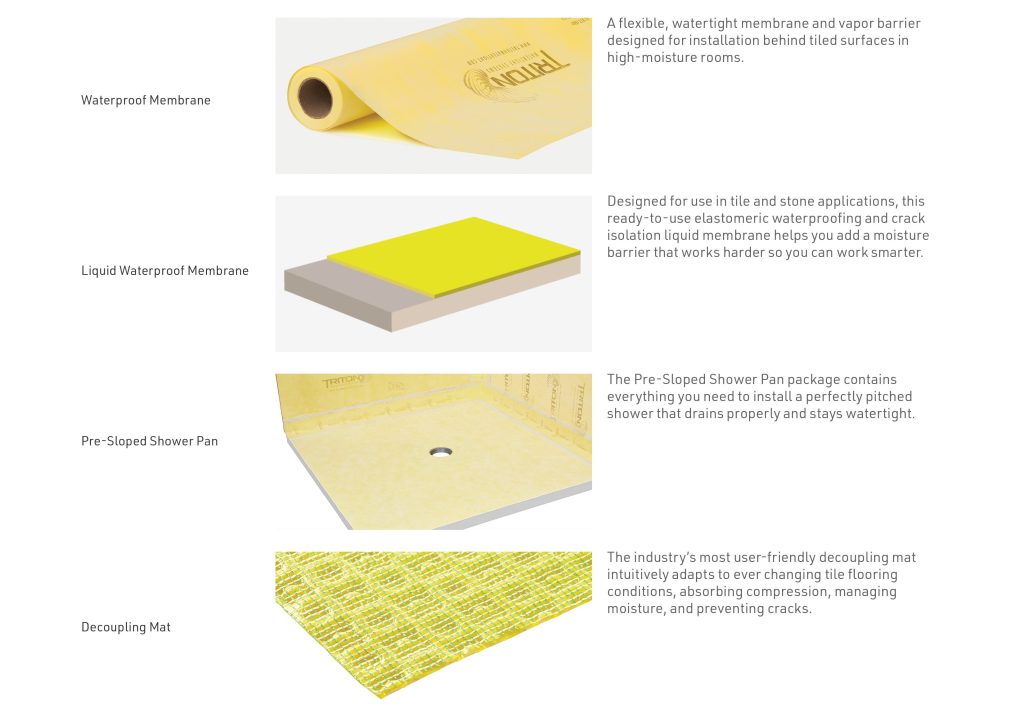

We continue to offer the same advanced waterproofing system for wet areas in the home, like bathrooms and showers. Products and services that were formerly MiTek’s Triton Watertight System are now MiTek’s Watertight System.

The branded technology name (TRITON®) is used for MiTek’s solutions where the MgO-based nanomolecular veneer cement technology is the primary material used to make the product like the TRITON® Backer Board and TRITON® Waterproof Backer Board.

In addition to the TRITON® Backer Board and TRITON® Waterproof Backer Board, we offer the same watertight system products.

See the before/now graphic above for logo and name change comparisons.

About MiTek

MiTek is a platform innovator and enabler that exists to transform the building industry with better building solutions. In 1955, MiTek transformed residential construction with the invention of the Gang-Nail plate, providing an affordable and scalable way to manufacture wood trusses. Today, MiTek delivers software, services, engineered products, and automated solutions that enable the building industry to improve efficiencies by optimizing the balance between off-site and on-site. With nearly 5,600 team members worldwide, MiTek collaborates across the building industry to enable and accelerate transformational breakthroughs in design and construction to transform the way the industry designs, makes, and builds. As a Berkshire Hathaway (NYSE: BRK-A, NYSE: BRK-B) company since 2001, MiTek has a record of continuous growth and innovation. Learn more at www.mii.com.

Chesterfield, MO – January 5, 2022 – MiTek welcomed Marie Jureit-Beamish, widow of John Calvin “Cal” Jureit, inventor of the Gang-Nail connector plate, on Wednesday, December 15, 2021, at its global headquarters in Chesterfield, Missouri. Jureit-Beamish transferred ownership of the original Gang-Nail connector plate and patent documents to MiTek to preserve the legacy of Jureit’s invention. Invented by Jureit in 1955, the Gang-Nail connector plate was the first metal tie that allowed for the building of wood trusses without the need for nails, screws, or glue. Jureit’s labor-saving invention revolutionized the building industry and served as the foundation of what would later become the company MiTek.

This news release was originally published on mii.com/newsroom; click HERE to read more

2020

MiTek® Expands Tolleson, AZ Location, Bringing New Jobs to the Market.

CHESTERFIELD, MO – August 21, 2020 – MiTek announced today an expansion of its Phoenix-based manufacturing operations later this year.

MiTek, a diversified global supplier of integrated software, service, engineered products and automated solutions to the building industry, announced today an expansion of its Phoenix-based manufacturing operations later this year.

Currently, MiTek produces connector plates and MiTek Builder Products in its 261,000 square foot plant located at 7890 West Lincoln, Tolleson, Arizona. MiTek will expand its presence into a neighboring building (7506 West Lincoln) which provides another 153,000 square feet, increasing operation footprint by nearly 60 percent.

“Our experience working with the City of Tolleson and the Arizona Commerce Authority over the years has been nothing short of exceptional,” said Mark Lee, President – Residential North America at MiTek. “When considering where to invest resources to advance our business operations, it was only natural to further our commitment to the Phoenix area.”

“Tolleson is known as a major employment center in the West Valley hosting more than 25 Fortune 500 companies who have grown their businesses in Tolleson. We are thrilled to learn of MiTek’s expansion and commitment to remain in the region, and just like they are committed to the success of their customers, we too believe that their success is our success,” stated Tolleson Mayor Anna Tovar.

The expanded Tolleson site will produce MiTek’s Lateral Systems (Hardy Frame®) and Custom MiTek Builder Products. MiTek will add 40 new full-time positions and make an initial $5 million investment in facility and equipment.

“MiTek’s decision to expand its Tolleson facility highlights the rapid manufacturing industry growth we continue to see here in Arizona,” said Sandra Watson, President & CEO of the Arizona Commerce Authority. “We’re proud to provide the ideal environment for innovative companies like MiTek to succeed. Thanks to the entire MiTek team for investing in our state and creating new opportunities for our residents!”

“We are excited to bring new jobs to a market with great talent,” Lee said. “We look forward to adding new team members who will contribute to our culture and enable us to accelerate our efforts to deliver technologies that provide much needed shelter and create thriving communities.”

MiTek operates around the world in North America, Europe, Africa, Asia, Australia and New Zealand. Its global locations are made up of manufacturing plants and distributions centers, along with software, engineering, and commercial offices.

MiTek® is a global provider of building solutions for the residential and commercial construction industries. Utilizing software, services, engineer products, and automated manufacturing equipment, MiTek partners with clients to deliver breakthroughs in building. With a rich 60-year history and a network of 6,500 team members worldwide, MiTek pairs local expertise with global capabilities. As a Berkshire Hathaway (NYSE: BRK-A, NYSE: BRK-B) company since 2001, MiTek has a record of continuous growth and innovation. Learn more at www.mii.com.

View the press release here (opens PDF)

MiTek® Acquires Hornet Saw Systems by iN4 Solutions, Inc.

CHESTERFIELD, MO – January 22, 2020 – MiTek announced today that it has acquired US-based Hornet Saw Systems and related software by iN4 Solutions, Inc.

MiTek® delivers technology solutions that optimize costs, shorten cycle times and eliminate waste through off-site prefabrication technology, resulting in a more efficient building process. The acquisition of Hornet Saw Systems and related software broadens MiTek’s range of automation solutions for component manufacturers helping increase their capacity and production efficiency.

Under the MiTek banner, Hornet Saw Systems will accelerate the adoption of wall panelization methods within the United States by connecting structural software design directly to cutting and marking capabilities.

“MiTek’s Automation Solutions Division welcomes the addition of the Hornet saw to our equipment range. The system’s advanced cutting and marking functions are tailored to wall panel production and represents great value for our customers. It aligns perfectly to our strategy for promoting off-site design and prefabrication in building.” – Cameron Wake, PresidentAutomation Solutions.

About Hornet saw systems by iN4 Solutions, Inc.

Hornet Saw Systems provides automated inking & sawing systems that deliver a high production, high quality supply of layout and parts cutting. Wall panel layout designs from MiTek software are seamlessly converted into pre-marked lumber that is ready to assemble. Learn more: www.hornetsaw.com

About MiTek

MiTek is a diversified global supplier of software, engineered products, services, and automation to the residential and commercial construction sectors. MiTek Industries’ passion for its associates’ well-being and its customers’ success is the company’s hallmark. A Berkshire Hathaway company (NYSE: BRK-A, NYSE: BRK-B) since 2001, MiTek has operations in more than 40 countries on six continents. Learn more: www.MiTek-us.com and www.MII.com.

2019

Chesterfield, MO – May 30, 2019 – MiTek USA today announced that it has released a new ProSeries™ fastener. The new ProSeries™ “WSTS Truss/Stud Screw” provides uplift resistance and lateral load resistance for the following connections: Truss-to-top-plate; rafter-to-top-plate; top-plate-to-stud; stud-to-bottom-plate.

The WSTS Truss/Stud Screw is tested in accordance with ICC-ES AC233 and AC13, and meets 2015 and 2018 IRC and IBC code requirements. The WSTS Truss/Stud Screw offers a “reverse thread angle” on opposite ends of the screw for greater resistance to withdrawal.

View the full press release (Opens PDF)

Chesterfield, MO – March 14, 2019 – MiTek has just received an Evaluation Code Report for the new Hardy Frame Cold Formed Steel Moment Frame and Cold Formed Steel Picture Frame products. Evaluation Code Reports enable designers to confidently specify “alternate building materials” not defined in the code, and they are accepted by the vast majority of building departments.

The MiTek Hardy Frame CFS Moment Frame Evaluation Code Reports can be downloaded at this link. These Evaluation Code Reports validate Hardy Frame Cold Formed Steel Moment Frame products as acceptable alternate building materials, allowing design professionals to rely on Hardy Frame’s allowable values and recommended installations, such as connections for transfer of forces.

“For Hardy Frame’s Cold Formed Steel Moment Frames, building departments now have third party validation that these products meet the intent of the code,” said Hardy Frame’s Jesse Karns. “These Code Reports will advance the use of our innovative Cold Formed Steel line by making specification and code-compliance easier for designers to achieve.”

View the full press release (Opens PDF)

Chesterfield, MO – March 13, 2019 – To aggressively accelerate the technology solution offerings it provides to home builders, MiTek today announced that it is committing substantial new resources to its home builder software group. In 2019, MiTek will add 35 new associates in the areas of software development, documentation, support, product management, and implementation services.

MiTek has long offered the top home builder software solutions, including award-winning systems for workflow management, document management, CRM/sales process automation, drafting and estimating service, web-based sales of new homes, and HVAC system optimization.

View the full press release (Opens PDF)

IBS Show Floor, Las Vegas, NV – February 12, 2019 – MiTek® Industries is a sponsor and participant in the 2019 BUILDER Concept Home at Inspirada, in Henderson, NV, called KB Home ProjeKt: Where Tomorrow Lives.

During the IBS show, MiTek’s participation will be demonstrated at the KB Home ProjeKt for visitors to the home site. The home tour times are Feb. 19, 20, and 21, from 10AM to 1PM. The address is 3131 Biancavilla Ave., Henderson NV. Transportation to and from the home is free through a Lyft promo code: KBHP2019. (See a virtual tour of KB Home ProjeKt now at this link.)

KB Home ProjeKt: Where Tomorrow Lives is a forward-looking concept home that breaks new ground in homebuilding through innovative partnerships, while also demonstrating the viability of a highly accelerated construction pace when moving from “dirt to dry-in.” The off-site construction framing process of this KB Home ProjeKt incorporated 3D-modeled and advanced panelized framing.

View the full press release (Opens PDF)

Chesterfield, MO – February 5, 2019 – MiTek Launches the “Cold Formed Steel Moment Frame™ Design Manager,” the Latest Shear Wall Design Software from Hardy Frame®.

MiTek USA’s Hardy Frame® brand has just launched its Cold Formed Steel Moment Frame Design Manager, a web-based software program that is the latest in a long line of shear-wall system solutions from MiTek. The new “Design Manager” supports the Hardy Frame CFS Moment Frame, the industry’s first cold-formed steel moment frame. Access the “Design Manager” at this link.

The new “Design Manager” is an interactive program used by building designers to enter lateral loading for wall elevations comprised of one or more floor levels of vertically stacked Hardy Frame Cold Formed Steel Moment Frames. The “Design Manager” is used to assemble a comprehensive compilation of loading requirements for multi-story walls. Submittal of the wall loading and geometry are routed directly to MiTek’s engineering department for them to provide the most economical shear wall design.

View the full press release (Opens PDF)

2018

Chesterfield, MO – November 13, 2018 – MiTek Joins Hanley Wood, KB Home, and ENTEKRA to Implement Advanced Off-Site Framing in the KB Home ProjeKt.

KB Home ProjeKt: Where Tomorrow Lives is a forward-looking concept home that will break new ground in homebuilding through innovative partnerships, led by KB Home, the industry leader in sustainability and innovation.

The off-site construction framing process of this KB Home ProjeKt will incorporate 3D-modeled, advanced panelized framing. Using a highly collaborative approach, the design and construction teams will account for all the framing details, as well as the MEP placement and HVAC optimization in the building process. Overall, KB Home ProjeKt will demonstrate the viability of a highly accelerated construction pace when moving from “dirt to dry-in.”

This dramatic shortening of traditional home framing cycle times is only possible through a truly collaborative effort across all disciplines, which is enabled in part by MiTek’s SAPPHIRE® suite of 3D structural component design and manufacturing software

View the full press release (Opens PDF)

Chesterfield, MO – October 24, 2018 – MiTek has announced that the next versions of its BuilderMT, Sales Simplicity, and Options Online software solutions will be fully cloud-based.

Over the next 18 months, MiTek will begin offering users of BuilderMT, Sales Simplicity, and Options Online the option to migrate to a modern, unified, integrated, cloud-based platform. This new version will be called BMT Cloud™, and it will be focused on mid-volume home builders. MiTek will soon issue a timeline for BMT Cloud™ development and integration.

View the full press release. (Opens PDF)

MiTek MatchPoint® DirectDrive™ System Offers Up To 40% Labor Reduction

At BCMC 2018, MiTek Will Preview New Energy-Saving and Equipment Safety Features.

CHESTERFIELD, MO – October 23, 2018 – MiTek Industries, Inc. today announced that it has advanced the labor-saving capabilities of its systems. With just over one year in the field, the MatchPoint® DirectDrive™ system is reducing shop floor labor by up to 40% for its users.

The MatchPoint® DirectDrive™ system complements MiTek’s MatchPoint BLADE™ Wood Processing System (an automated saw and component manufacturing system) and MiTek’s Wizard PDS Auto Jigging system. Visit BCMC booth 206 to learn more.

View the full press release (opens PDF).

Missouri’s Largest Home BuilderMasters Homebuyer Options, as It Builds With Continuous Profitable Improvement

CHESTERFIELD, MO – September 12, 2018 – MiTek USA today announced that McBride & Son Homes, already a customer of a wide range of MiTek building products, has affirmed its market leader status with the implementation of MiTek’s SAPPHIRE® Build software solution. (Read the full case study and watch a video at this link.)

McBride & Son Homes will start 900 homes in 2018, up from 742 in 2017, making the Company the 64th largest US home builder. McBride employs 225 people, a remarkably lean operation, with a ratio of just four 2018 housing starts for every employee.

View the PDF here.

The Chairman’s Choice Award Is Given to Trade Partners That Have Demonstrated Excellence

CHESTERFIELD, MO – September 6, 2018 – MiTek USA today announced that it was honored to recently receive the D.R. Horton 2018 Chairman’s Choice Award, a distinguished privilege. The award recognizes trade partner excellence, and MiTek was selected for its tremendous work as a national partner of D.R. Horton’s; for increased efficiency and technology opportunities introduced to many D.R. Horton divisions; and for MiTek’s overall responsiveness.

MiTek was cited for superior service delivering product solutions on a national scale from MiTek’s expansive offering of Builder Products, which include hangers, shear walls, fasteners, and software solutions. This 2018 Chairman’s Choice Award comes just three years after MiTek initially engaged D.R. Horton with its MiTek Builder Products line of hangers and fasteners. D.R. Horton is the largest home builder in the United States, ranking No. 1 on the Builder 100 list since 2002. In calendar 2017, D.R. Horton closed more than 47,000 homes, with revenues of over $14 billion.

View the PDF here.

CHESTERFIELD, MO – August 29, 2018 – MiTek USA just announced that its Hardy Frame brand now offers a range of seven products in a “full spectrum” offering of lateral-load solutions for light-frame, multistory construction. Two of the Hardy Frame solutions introduced here – the Hardy Frame® CFS Moment Frame™ and the Hardy Frame® CFS Picture Frame™ – are entirely new to the market.

“MiTek is the innovator in the field of lateral-load solutions. With this full spectrum of solutions, anyone designing or constructing light-frame, multistory structures now has more choices, more advantages, and better value,” said Scott Miller, MiTek’s Senior Vice President of Engineering. “Our new cold-formed steel solutions are especially innovative, allowing easy, on-site assembly. We stand alone in the industry with this new alternative to structural steel moment frames.”

View the PDF here.

The Latest Version of MiTek® Deck Designer™ Adds Customization of Deck Levels and the Direction, Size, and Color of Planks, Among Other New Features

CHESTERFIELD, MO – August 22, 2018 – MiTek® announced that it has released a new version of the highly popular MiTek® Deck Designer™ (formerly USP® Deck Designer) that offers a series of improvements.

MiTek® Deck Designer™ is a free online interactive software program that helps building material retailers and their customers design their dream decks. The newest version of the software allows advanced customization of deck levels, as well as the direction, color and size of deck planks, among other features.

Read more here.

MiTek Announces the Hardy Frame® CFS Moment Frame™,the Industry’s First Cold-Formed Steel Moment Frame

CHESTERFIELD, MO – July 19, 2018 – MiTek USA’s Hardy Frame® brand now offers the CFS Moment Frame, the industry’s first cold-formed steel (CFS) moment frame.

Built upon the success of Hardy Frame’s HFX Panel, the new CFS Moment Frame is the industry’s first cold-formed steel prefabricated moment frame.

View the PDF here.

CHESTERFIELD, MO – March 23, 2018 – MiTek® USA just announced that it has released an updated MiTek USP Catalog App for Apple, Android, and Windows mobile devices.

Now with improved navigation and graphics to search MiTek’s connector product line, the no-cost MiTek USP Catalog App features new product and application illustrations, installation instructions, and updated fastening schedules, as well as load ratings and reference conversions.

The MiTek USP Catalog App also offers navigation to search the entire MiTek USP product catalog, as well as cross reference specifications and easy, on-the-fly product look-ups. Engineered wood products (EWP) and plated truss connectors are also included in the App. Users can email MiTek USP product pages directly from the App.

- Free download on iTunes App Store. Search for “MiTek USP Product Catalog.” iPad and iPhone Requirements: IOS 7.0 or later.

- Free download in Google Play. Search for “MiTek USP Product Catalog.” Android phone or tablet Requirements: 4.0.3 (Ice Cream Sandwich) or later.

- Windows Phone or tablet Requirements: 10 or later. Free download in Windows Store. Search for “MITEK USP Product Catalog.”

Download the complete press release here.

CHESTERFIELD, MO – January 25, 2018 – MiTek® USA just announced that its SAPPHIRE Supply software solution has added new features and functionality for its lumber and building material “ProDealer” users.

Designed specifically to meet the needs of lumber and building material dealers, SAPPHIRE Supply is a single-source software solution that uniquely combines complete, multi-category materials estimating and structural frame design. SAPPHIRE Supply also incorporates the building material supplier’s product SKUs (and pricing) to create a complete “whole house” quote, while performing analysis and design on a wide range of structural products, including leading proprietary engineered wood products (EWP), dimension lumber, and metal connectors and hangers.

Download the full press release here.

CHESTERFIELD, MO – January 3, 2018 – MiTek® Industries, a Berkshire Hathaway company, today announced that Rachel Seward has joined MiTek as the Vice President of Enterprise Communications and Philanthropy. In this newly created role, Ms. Seward will develop clear channels, and standards for communicating internally and externally, with a special focus on helping convey the “One MiTek” story with clarity, passion, and consistency on a global scale.

Read more here.

CHESTERFIELD, MO – January 3, 2018 – MiTek® Industries, a Berkshire Hathaway company, today announced that Richard Sullivan has joined its leadership team as Vice President, Enterprise Operational Excellence. In this newly created role, Mr. Sullivan will come alongside and partner with MiTek’s global Business Unit leaders as a resource and internal champion to assist them on their journeys of continuous improvement.

Read more here.

2017

The New “Fire Wall Hanger for Beams and Purlins” Can Support Loads of More Than 5,700 Pounds

Chesterfield, MO – November 29, 2017 – MiTek USA, a leading manufacturer of code-approved structural connectors, anchors, and epoxy, and a developer of software tools for design and workflow, today announced the national availability of a new FWH Fire Wall Hanger connector: FWHBP, for Fire Wall Hanger for Beams and Purlins. (Link to product description.)

The FWHBP can transfer loads of more than 5,700 pounds into supporting walls by bearing on the wall’s top plates and directly attaching to the stud pack or post below (see Figure 1). As with MiTek’s original FWH hanger, the advanced design allows users to install the new hangers before the drywall is attached, eliminating an extra framing step, shortening the process, and allowing a project to be completely framed-up and weather-tight before the drywall shows up on site.

Read more here.

CHESTERFIELD, MO – November 13, 2017 – MiTek® today announced that its outgoing president, Dick Marriott, has won the 2017 Dick Bowman Industry Enthusiast award, a prestigious honor awarded annually by the Structural Building Components Association (SBCA).

“The Dick Bowman Industry Enthusiast award was created in 2005 in honor of Dick Bowman, long-time SBC Magazine and BCMC exhibit space salesman, who was the epitome of enthusiastic support for the structural building components industry. Dick Bowman faithfully served our industry until his unfortunate death in January of 2004,” according to the SBCA.

Before recently announcing his retirement, Dick Marriott had been President of MiTek USA, Inc. Prior to that, Mr. Marriott had also served as Senior Vice President of Sales for MiTek USA until 2008. He first joined MiTek in 1978 as a sales engineer.

“Dick Marriott’s lifetime of service to MiTek and to the community of customers we serve is revered in the building industry, and rightfully so. This award is well-earned by Dick, and I know I speak for the entire MiTek family, in offering a heartfelt thanks to Dick for all he has given to us and to this industry, and especially for the example he has set for his fellow MiTek team members,” said Maged Diab, President of MiTek USA.

“This award will honor a supplier individual who over the years has supported BCMC [the Building Component Manufacturers Conference] and the structural building components industry as a whole with enthusiasm and integrity in an unselfish and positive manner and has brought an all-around good attitude and joy to the show. The selection committee for the Dick Bowman Industry Enthusiast Award is the SBCA Board of Directors, SBCA Past Presidents and the BCMC Committee,” the SBCA added.

The past recipients of this award have included Joe Kannapell (2013), Carl Schoening (2014) Jerry Vulgaris (2015) and Mike Martz (2016).

Download the press release here.

Lateral Loads from Wind and Earthquakes Require Wood-Framed Structures to be Properly Braced. Hardy Frame® Prefabricated HFX Narrow Shear Wall Panels Offer a Ready Solution in Limited Spaces.

CHESTERFIELD, MO – November 7, 2017 – MiTek announced today that it has just published a new Hardy FramePrescriptive Design Guide that provides an overview of braced wall design, a flow chart of the design and specification process, and specific instructions to properly apply the Hardy Frame Alternative Braced Wall Solution.

The Hardy FramePrescriptive Design Guide describes the need to locate Braced Wall Lines, determine the Braced Wall Length, and identify the available Braced Wall Segments within each line. When the total length of the Segments is insufficient to meet the Braced Wall Length requirement, the Hardy Frame Alternative Braced Wall is the solution to meet the International Residential Code (IRC).

Garage fronts commonly have limited space that is problematic when specifiers need to meet Braced Wall Lengths and Braced Wall Panel requirements. The Hardy Frame HFX Prefabricated Narrow Shear Wall Panel – manufactured under a quality-control program – is a proven solution for these conditions.

Read more here.

CHESTERFIELD, MO – September 28, 2017 – MiTek today announced that it has launched a new line of fasteners, called MiTek ProSeries™. MiTek ProSeries™ includes MiTek Washer Head structural wood screws, MiTek Bugle Head structural wood screws, and MiTek Hex Head structural wood screws.

Read more here.

Chesterfield, MO, September 21, 2017 – MiTek USA today announced that MiTek Builder Products now offers a Hardy Frame Special Moment Frame Design Manager online tool for designing Hardy Frame Special Moment Frames (HFSMF). Hardy Frame Special Moment Frames are used in the design, construction, and retrofit of single- and multi-story wood-frame structures in residential and light-commercial markets. Engineered to resist significant lateral forces from high wind and seismic loads, Hardy Frame Special Moment Frames are state-of-the-art, pre-fabricated, pre-engineered systems that utilize next-generation SidePlate® moment connection technology.

The Hardy Frame Special Moment Frame Design Manager is highly interactive and replaces tedious manual input forms. As the user enters dimensions, the Hardy Frame Special Moment Frame is instantly drawn to scale. The input is continuously checked for consistency and accuracy, preventing costly specification errors and delays. Heights, inside and outside widths, and other important dimensions are displayed, including clearance reductions for nailers and SidePlates®.

CHESTERFIELD, MO – September 7, 2017 – MiTek’s DIY Technologies, the market-leading, web-based design software for decks and outdoor living spaces, today announced that more than four million projects have run through the system, as consumers, DIYers, ProSumers, and professional contractors have all used MiTek’s software to optimize their design and generate material lists and building permit / code documents needed for the success of their projects. DIY Technologies is the underlying technology that powers USP Deck Designer™. (Download USP Deck Designer at this link at no cost.)

DIY Technologies deck design software is just one of a far-reaching set of software solutions offered by MiTek to design, specify, and obtain “bills of material” (product lists) for construction projects of all types and sizes. The wide spectrum of MiTek’s other software also includes specification, workflow management, and sales automation solutions for builders; estimating software for builder material dealers, as well as design and automation software for the wood structural frame and component manufacturing

CHESTERFIELD, MO – June 13, 2017 – MiTek Industries, Inc. today introduces the MatchPoint™ DirectDrive system. The MatchPoint DirectDrive™ system complements the MiTek’s MatchPoint BLADE™ wood processing system (an automated saw and component manufacturing system), as well as MiTek’s Wizard PDS Auto Jigging system.

Now, with the MatchPoint DirectDrive system, users can access new software and a material-handling system that fully rounds out roof truss component manufacturing, while also significantly minimizing labor. Plus, when delivering cut wood truss members from the saw to the truss make-up table, the MatchPoint Blade system offers sorting, optimizing, and printing capabilities which allow for unrivaled accuracy and speed. Users of MatchPoint DirectDrive system can also experience even greater increased output, achieved with a potentially reduced workforce. The MatchPoint DirectDrive system all but eliminates truss manufacturing “set-up time,” a major factor that can

limit truss production output.

With MiTek’s Virtual Plant software (MVP), users can also manage the truss manufacturing process, a.k.a. work in progress (WIP), far better than before, while increasing manufacturing capacity within a manufacturing facility’s existing footprint. Review the MatchPoint™ DirectDrive System at this link, which includes a video overview.

Chesterfield, MO – June 8, 2017 – MiTek today announced that its INCREDIBOND® product has joined MiTek Builder Products’ lineup of high-performance epoxy anchoring solutions, where MiTek offers epoxy solutions

for use in a wide range of projects, from heavy-industrial seismic and wind applications to household projects.

INCREDI-BOND is a high-strength, two-component epoxy specifically designed to be a bonding agent for almost all household materials including wood, steel, concrete, brick, stone, and CMU block. INCREDI-BOND, which is moisture-insensitive, has a two-year shelf life when stored in unopened containers in dry conditions between 40°-95°F.

INCREDI-BOND offers over 1,000 psi bond strength in two days, a quick initial cure time of two hours at 75°F, and a convenient 20-minute working time. INCREDI-BOND’s non-sag formulation makes it an excellent epoxy for overhead patching and repairs. Plus, there’s easy tool clean up with M.E.K. or WD-40.

INCREDI-BOND joins these other MiTek epoxy solutions:

• CIA-GEL 7000-C™, code-compliant epoxy designed for tension and

shear loads due to wind or earthquake (Seismic Design Category C-F).

CIA-GEL 7000-C is designed to attach anchor bolts into concrete that

is, or may become, cracked due to cyclic loading from wind or

earthquakes.

• CIA-GEL 7000™, masonry-approved epoxy designed to attach anchor

bolts into fully grouted concrete masonry units (CMU). CIA-GEL 7000

has ICC-ES AC58 approval for seismic, sustained load, elevated

temperature, and freeze-thaw suitability conditions.

• CIA-GEL 6000-GP™, general purpose, quick cure epoxy for general purpose

structural applications that require quick load times and for

doweling applications that require state DOT approval.

• CIA-EA™, epoxy acrylate structural adhesive for high-strength, fast-cure structural

anchoring of threaded rod and deformed rebar into uncracked concrete.

To calculate how much epoxy is required on any job, MiTek now offers an

Epoxy Quantity Estimator, available at this link.

“INCREDI-BOND joins our very strong epoxy product offering, where users can find an epoxy solution for virtually any projects, from industrial-grade commercial construction, to household uses. We really are a one-stop shop

for high-quality epoxies for a wide range of applications,” said MiTek’s Marty Ruch.

Chesterfield, MO, May 8, 2017 – MiTek® USA announced today that its MiTek Builder Products division has won multiple awards from the North American Retail Hardware Association (NRHA) as part of its 2017 Packaging and Merchandising Awards Program.

- MiTek has been awarded a Gold Award for its “Bin Display.”

- MiTek has been awarded a Silver Award for its “Carton Display.”

- MiTek has been awarded an Honorable Mention for its “Packaging.”

The judges’ criteria for the award included: Overall Shelf and Sales Appeal, Graphic Design, Innovation, Packaging Efficiency, Shelf Life, and Selling Feature. The awards will be given at the All-Industry Conference and National Hardware Show, May 9-11 in Las Vegas.

“It has always been evident to our MiTek associates and our customers that we take enormous pride in enabling strong sales for their businesses,” said Maged Diab, President of MiTek USA. “These NRHA national awards are indeed an honor, doubly so because they bring recognition to the efforts we have made to drive the success of ou retailers and their customers.”

CHESTERFIELD, MO – March 28, 2017 – MiTek USA today announce that Cincinnati-based McCabe Lumber has implemented MiTek’s SAPPHIRE Supply, resulting in a 50% reduction in the time required to generate estimates and material take-offs. McCabe Lumber is a longtime user of MiTek’s SAPPHIRE Structure for designing and manufacturing prefabricated components.

Using SAPPHIRE Supply, the newest SAPPHIRE module, McCabe can now create the most-accurate 3-D BIM structural frame in the building industry. With SAPPHIRE Supply, a wide range of structural products can be designed for roofs, floors, and wall applications, including proprietary EWP products, dimensional lumber, and MiTek’s USP Structural Connectors’ metal connectors. SAPPHIRE Supply can also estimate non-structural materials such as drywall, roofing, and housewrap. A flexible formula-builder gives SAPPHIRE Supply user the power to define their own accumulation rules, further increasing accuracy.

Watch a video about McCabe Lumber’s use of SAPPHIRE Supply: link.

McCabe Lumber has a staff of 120 and generates $40 million in annual revenue; customers are predominantly high-end custom production home builders and professional remodelers.

“With SAPPHIRE Supply, our material counts and delivery stages are so accurate, we see a clear path to reducing the error and waste rate from as much as 8% down to 2%, which is near-perfect accuracy,” said Dave Renchen, McCabe Lumber’s Estimating Manager.

“SAPPHIRE Supply uses a single shared structural model, and that offers McCabe a unified solution for efficient, consistent and accurate modeling, estimating, on order fulfillment across their organization,” explained MiTek’s Brian McCormick. “SAPPHIRE Supply eliminates the classic problem of inconsistent sales estimating, because it delivers accurate modeling and estimating on every structure.”

“Now our sales team is not spending hours on estimates; instead, they are selling more jobs and expanding relationship, often by using SAPPHIRE Viewer, a free download for reviewing SAPPHIRE models,” added McCabe Lumber’s Dave Renchen.

For information about SAPPHIRE Supply, and to read the full McCabe Lumber case study, visit link, or contact Brian McCormick; BMcCormick@MII.com.

CHESTERFIELD, MO – April 6, 2017 – MiTek USA today announced the launch of the MiTek Builder Technology Summit. The 2017 MiTek Builder Technology Summit is an inaugural event that will showcase the very latest technology for home building design, estimating and workflow. The Summit will feature technology exhibits and demonstrations, as well as a wide range of educational/training sessions.

The technology Summit will feature MiTek’s builder-focused companie and software platforms including BuilderMT, Cubit, DIY Technologies, Sales Simplicity, SAPPHIRE Supply, SAPPHIRE® Build (KOVA), and Wrightsoft.

In addition, integration partner-companies that have linked to MiTek solutions will also be featured, including Avid Ratings, CG Visions, Build Intelligence (DOMO), Event 1 Software (Liberty Reports) LandDev, Punchlist Manager / Inspection Manager, Specitup, and Western Computer.

The three-day MiTek Builder Technology Summit is focused on information sharing. The Summit will kick off by hearing from current customers, presenting alongside their technology providers, to highlight their experiences and the impact these technologies have had on their businesses.

MiTek is urging attendance from senior home building managers, with a special focus on CEOs, COOs, CIOs, CTOs, as well as personnel from the sales, purchasing, scheduling, and quality-assurance departments.

The MiTek Builder Technology Summit will be held at the Naples Beach and Golf Hotel, in Naples Florida, September 19-22, 2017.

“This Summit is designed as a technology exposition both in addition to a training/educational event.,” said MiTek’s Rob Hooker. “We intend to draw attendees from elite home building companies that want to see the latest technology designed to cut cycle-times, reduce the need for skilled labor, and drive higher profit margins. We’ll see you in Naples!”

Learn more: www.MiTekBuilderTechnologySummit.com.

CHESTERFIELD, MO – March 15, 2017 – MiTek announced today that it has launched a new USP Adhesive Anchor Design program. The program, a free download, is a powerful design tool that provides optimized epoxy connection solutions for anchors post-installed into concrete using CIA-GEL 7000-C. The time-saving USP Adhesive Anchor Design program determines the required anchor rod steel grade, diameter, and effective embedment depth, based on applied factored tension, shear, and moment loads. Visit the program’s website to watch a video: Link.

Compliant with the 2012 IBC code requirements (ACI 318-11 Appendix D), the USP Adhesive Anchor Design program can be used in high-seismic regions (Seismic Design Categories C, D, E, and F), and it can accommodate up to eight anchor rods with slotted anchor plate holes. The USP Adhesive Anchor Design program also accepts factored loads for tension, shear, and moments, using ACI 318 Chapter 9.2 load combinations.

The USP Adhesive Anchor Design program also creates a comprehensive design report that can be emailed as a PDF for job submittal.

With French and Spanish language options, the software automatically scans for updates and will alert the user when updates are available.

“The USP Adhesive Anchor Design program can guide users through the process of specifying material and geometry properties, anchor plate/bolt groupings and applied factored loads,” said MiTek’s Jim Collins. “The calculation generates a completely optimized set of CIA-GEL 7000-C epoxy solutions for threaded rod and re-bar anchors and a quick way to filter the results based on steel type and diameter. Color coding is used to sort the optimum designs.”

Chesterfield, MO, February 21, 2017 – MiTek® USA announced today that Hardy Frame® has added an innovative design to its Hardy Frame Special Moment Frame (SMF) product offering. By designing and fabricating the beam-to-column SMF connections – at the top and the bottom of the frame – the efficiencies in the utilization of the column are significantly increased. With increased column efficiencies, the designer can economize special moment frame member sizes, the number of frames required in a wall line, or achieve higher capacities when lateral forces are high and shear-load demands are extreme.

MiTek USA’s Hardy Frame Shear Wall System has long offered Hardy Frame Prefabricated Narrow Shear Wall Panels and Hardy Frame Prefabricated Special Moment Frames, along with installation accessory items, steel connectors, post installed epoxy and cast-in-place anchoring solutions. The Hardy Frame Shear Wall System is now

expanding to include the new “Hardy Frame Picture Frame,” a four-sided special moment frame with special moment connections at all four corners. Anchorage to the concrete for tension and shear can be a simple pinned base. The innovative addition of a beam with special moment connections (which replaces the need for an engineered, steel-reinforced concrete grade beam) provides the advantages of a fixed base connection, along with an easier field installation and a reduced need for inspections.

Interest in Hardy Frame Special Moment Frame design solutions is at its highest point since the product was introduced in 2008 due to “soft story retrofit” ordinances adopted within a growing number of California building jurisdictions. MiTek has developed a new special website ( link) for all soft-story retrofit related issues to showcase its structural retrofit solutions: http://www.HardyFrame.com/softstory. (A recent illustrated Journal of Light Construction feature article explains the Hardy Frame SMF installation process, in detail.)

“With this exciting innovation, we now offer Hardy Frame products to meet engineers’ daily design challenges, from creating architectural openings for large windows and doors for new structures, to strengthening soft story buildings for preparation of severe seismic events,” said Maged Diab, President of MiTek USA.

CHESTERFIELD, MO – January 23, 2017 – MiTek Industries, Inc. (“MiTek”), a diversified, global business supplying a wide range of engineered products; proprietary business management and design software; and automated equipment to the construction and industrial markets announced today that it has acquired Wrightsoft Corporation (“Wrightsoft”). Headquartered in Lexington, Massachusetts, Wrightsoft is the market pioneer and leading provider of software for residential and commercial energy code compliance and HVAC system design.

“I’m thrilled with the acquisition of Wrightsoft, as this expands our technology leadership into a new area of residential and commercial construction for MiTek: energy load calculation and HVAC system design,” stated Tom Manenti, Executive Chairman of MiTek. “Aligned with our current software platforms, Wrightsoft will provide MiTek a new software extension into this essential aspect of residential and commercial construction. The resources MiTek brings to bear, coupled with Wrightsoft’s deep industry relationships, unique expertise, and proprietary software, will provide unequalled capabilities and efficiencies to MiTek’s growing residential and commercial customer base.”

“We are delighted to welcome Bill Wright and his leadership team to the MiTek family, and we look forward to working with them to continue providing exemplary service to their customers and growing Wrightsoft’s business,” Manenti commented.

Bill Wright, founder and President of Wrightsoft added, “We have successfully partnered with MiTek for a number of years now, and I am excited Wrightsoft has joined the MiTek and Berkshire Hathaway family. MiTek’s values-based approach to leadership combined with its vision of providing unsurpassed, value-added technology to the global residential and commercial construction industry, make this a perfect fit for Wrightsoft and

all its employees.”

About Wrightsoft

Founded in 1985, Wrightsoft provides Air Conditioning Contractors of America (ACCA)-approved software that combines residential and commercial energy load calculation with design functionality in a single, proprietary program known as Right-Suite Universal®. This technology allows the HVAC contractor to properly calculate energy loads, accurately design and size HVAC systems, efficiently produce parts takeoff lists and proposals, and generate all necessary professional documentation and reports. Learn more: www.Wrightsoft.com.

CHESTERFIELD, MO – January 11, 2017 – MiTek Industries, Inc. (“MiTek”), a diversified, global business supplying a wide range of engineered products; a proprietary business management and design software; and automated equipment to the construction and industrial markets, announced today that it has acquired DIY Technologies (“DIY”). Headquartered in Tucson, Arizona, DIY is a market leader in web-based design software for a wide range of

home improvement and renovation projects.

“I am delighted with the acquisition of DIY, which has an enviable leadership position as a provider of on-line design software to the do-it-yourself, home improvement market. This acquisition is yet another extension of our leading position in technology serving the residential construction industry,” stated Tom Manenti, Chairman and CEO of MiTek. “DIY has established long-term relationships with some of the nation’s largest and most-respected retailers and building-products manufacturers. The combination of MiTek’s software and capital resources, along with DIY’s comprehensive web-based software, will provide unparalleled technology tools that will enhance our customers’ value proposition.”

“We are thrilled to welcome Michael Heisler and his team to the MiTek family and look forward to supporting their business model while expanding their software offerings and services, as we continue to grow DIY’s business,” Manenti commented.

Michael Heisler, CEO and founder of DIY added, “This acquisition is the culmination of more than ten years of successful partnering with MiTek. I am excited that DIY and all our employees have joined the MiTek and Berkshire

Hathaway family. I have seen how MiTek truly ‘lives’ its core values, and because of this and its compelling vision of providing unrivaled, highly productive technology to the global residential and commercial construction industry, I know MiTek is the ideal home for DIY.”

About DIY

Founded in 1998, DIY provides web-based software focused on do-it yourself home improvement projects, including: decking, fencing and other outside living projects. DIY’s innovative software provides its users a wide range of capabilities, from generating project layout sheets, to creating cut sheets and material lists, to identifying and locating specific manufacturer’s products at local retail and building material stores. Learn more: www.DIYonline.com.

CHESTERFIELD, MO – January 9, 2017 – MiTek Industries, Inc. (“MiTek”), a diversified, global business supplying a wide range of engineered products; proprietary business management and design software; and automated

equipment to the construction and industrial markets announced today that it has added Mark Thom to its leadership

as the new CEO. The current CEO, Tom Manenti, will assume the role of Executive Chairman for 2017. Mr. Manenti will continue to report to Warren Buffett.

Mr. Thom has a rich background of executive leadership and achievement in management and sales. For 16 years,

he led teams within the former Tyco Healthcare, a nearly $12 billion global manufacturer of medical and pharmaceutical products, where Mr. Thom received top honors as a sales person. He began his career at Tyco Healthcare after graduation from Miami University and rose to the role of President of the Tyco’s Vascular Therapy division in 1998, just eight years after he left college. Soon after Tyco Healthcare acquired Mallinckrodt Medical, Mr. Thom was named president of Mallinckrodt’s Diagnostic Imaging Business, and he was later named Group President, Tyco Healthcare in early 2003. In recent years he served as leadership consultant to the MiTek senior leadership team, where he learned the MiTek business and its culture.

Mr. Thom assumes the CEO role at MiTek at a fortuitous time for the company. With notable acquisitions, diversification, and organic growth, MiTek has doubled in size since 2011, and has a strategic plan in place to

double again over the next five years. His addition now provides leadership continuity as Mr. Manenti retires in January, 2018.

“The naming of Mark to the CEO position addresses one of my key business imperatives – Leadership Development and Succession Planning – a well-developed and widely used road map for MiTek leadership into the future,”

said Tom Manenti, Chairman and CEO of MiTek. “More importantly, Mark is simply a top performer, in the very elite class of executives in multiple categories of corporate operations and effective leadership. I was thrilled when Mark accepted the CEO position. It was a banner day for MiTek worldwide!”

About MiTek

MiTek is a diversified global supplier of software, engineered products, services, and equipment to the residential, commercial, and industrial construction sectors. MiTek Industries’ passion for its associates’ well-being, and its customers’ success, is the company’s hallmark. A Berkshire Hathaway company (NYSE: BRK-A, NYSE: BRK-B) since 2001, MiTek has operations in more than 40 countries on six continents. Learn more: www.MiTek-us.com and www.mii.com.

2016

CHESTERFIELD, MO – December 16, 2016 – MiTek today announced that it has opened a new warehouse and distribution facility in Atlanta, GA. This new facility is the third warehouse opened by MiTek in the last 13 months, and it joins other strategically placed manufacturing, warehousing, and distribution facilities already located in New Jersey, Florida, Indianapolis, Minnesota, Houston, Phoenix, and California.

The new Atlanta facility enables rapid distribution of MiTek building products to customers within a 500-mile radius. Fully functional on February 1, 2017, the new facility offers products that include USP Structural Connectors, USP

Epoxy and fastener products, as well as MiTek truss connector plates. The facility will primarily serve MiTek’s two-step customers and support MiTek’s rapidly expanding sales network.

The new warehouse offers 45,600 sq. ft. of space, of which 3,500 sq. ft. will be dedicated to offices, training, and customer support. The address of the new facility is 4380 International Parkway, Atlanta, GA 30354. The warehouse has immediate access to I-75, I-285, I-85, and is one mile from the Hartsfield-Jackson Atlanta International Airport.

“This is the third new MiTek warehouse and distribution center we have opened recently. With its strategic location, it provides us with even more coverage areas for one-day or two-day delivery of MiTek products,” said Todd Asche, Senior Vice President of Operations. “This new warehouse and distribution facility is clear evidence that MiTek is

‘on the march,’ with a goal of distributing our products at an expansive geographical scale.”

CHESTERFIELD, MO – August 25, 2016 – MiTek® today announced the latest member of its growing Retail Sales Team. Chris McCorkle is the new MiTek Builder Products Director of National Accounts for the Lowe’s account (NYSE: LOW). Mr. McCorkle has a long history working closely with Lowe’s; he resides in the Mooresville NC community, here the Lowe’s corporation is headquartered.

Mr. McCorkle joins MiTek from Jarden Applied Materials, Lawn and Garden Consumer Products, where he was national Account Manager responsible for “big box,” distribution, and hardware coop accounts.

Previously, Mr. McCorkle spent 12 years with Valspar (NYSE: VAL), among the world’s largest global coatings manufacturers, and a strategic partner of Lowe’s. At Valspar, he served as National Account manager for Lowe’s, as well as marketing manager. Mr. McCorkle was responsible for managing the Floor Coatings, Primer and Specialty

Coatings program with Lowe’s.

“We couldn’t be more honored to have Chris on our MiTek Builder Products team,” said Marty Ruch, MiTek Builder Products’ VP, Retail Sales and Merchandising. “He brings a tradition of service and a wealth of highly specific experience working with A-list brands. We look forward to having Chris expand and deepen our relationship with

Lowe’s.”

CHESTERFIELD, MO – August 23, 2016 – MiTek announced today that it has just released a new version (1.5) of its widely used MiTek Specifier™ software. With MiTek Specifier, users can design beam-to-joist type hangers, input load requirements, and generate connector schedules that can easily be input into CAD drawings. MiTek Specifier also lets users define product lists, group connectors by project, print pick list reports, and compare USP’s products alongside its competitors’ offerings. The new version of the MiTek Specifier software contains these enhancements:

- Hanger specs. Users can use a Quick Select design feature that accesses USP’s full hanger product line. USP Specifier lets users define product lists, group connectors by project, print pick list reports, and compare USP’s products to competitors’ offerings.

- Full catalog. Users can access a wealth of new connector products, because the entire 2015-2016 Product Catalog is available in MiTek Specifier today.

- Updated codes. The latest building codes have been updated in MiTek Specifier’s design data, presented with an improved graphical display.

As with past versions of MiTek Specifier, users will find quick views of code compliance reports, as well as access to a reports-generating tool that is highly configurable. With USP Specifier, it’s also easy to prepare documents for engineers of record and building designers or to import cost and price information for comprehensive project management.

To install USP Specifier 1.5, visit the Specifier software page. New users will receive an authorization code via email.

“The MiTek Specifier software offers access to our entire catalog of hangers and connectors, while providing tools that simplify code compliance,” said Robert Shupe, VP of Engineering Software Services. “We’re delighted to offer the enhanced Version 1.5, which is further evidence of our commitment to our customers in their efforts to build safe, code-compliant structures.”

CHESTERFIELD, MO – August 4, 2016 – MiTek today announced that its new distribution facility in Plainfield, IN is now fully operational. Offering distribution to a 500-mile radius, the new facility will provide same-day or next-day delivery for a wide range of products, including USP Structural Connectors, USP Epoxy and fasteners, and MiTek truss connector plates. Serving MiTek’s two-step customers, and supporting MiTek’s expanding sales network, the new facility also offers nearly 53,000 square feet of space and 6,500 square feet of office space, where MiTek will provide customer training and support. The address of the new facility is 2363 E Perry Rd., Plainfield, IN 46168.

The new MiTek distribution facility features 15 dock doors, one oversized drive-in door, and expansive staging bays. Excellent access to key transportation routes is available, including Indianapolis International Airport, I-70, I-455, SR 37, SR 67, and nearby downtown Indianapolis.

“MiTek’s new Plainfield, IN facility will allow rapid delivery – often same-day service – to an expansive 500-mile radius from our new location,” said Todd Asche, Senior Vice President of Operations. “With our recent Houston distribution facility coming fully online and our new Indianapolis facility fully operational, we have made great strides in expanding the reach for MiTek and the products offered by our MiTek Builder Products division.”

CHESTERFIELD, MO – June 8, 2016 – MiTek today announced that its expanded Houston, TX warehouse is now fully operational, providing more stock and improved delivery for a wide range of products, including USP Structural Connectors, USP Epoxy and fasteners, MiTek truss connector plates, and Hardy Frame shear wall systems.

The new warehouse offers sameday or next-day delivery service to a wide range of states, including Texas, Louisiana, Alabama, Oklahoma, Arkansas, Nebraska, and Missouri. As an added convenience, the warehouse will also offer local customers the expediency of “will call” delivery.

MiTek chose to expand the Houston warehouse to better service the needs of dealers, builders, local contractors and DIY markets, where MiTek has seen increased demand for its products, specifically those which address the stringent requirements of the coastal wind codes.

“MiTek has been adding more SKUs and shortening delivery times to an expanded list of locations and states, and our Houston facility provides yet one more part of our plan to deliver exceptional and prompt order fulfillment across multiple states,” said Todd Asche, Senior Vice President of Operations. “Plus, we now have advanced inventory monitoring and processing systems in place, which accelerate fulfillment times across multiple MiTek product lines.”

Chesterfield, MO, April 26, 2016 – MiTek® today announced that its MiTek Builder Products division offers a range of solutions for building owners, structural engineers, and contractors to design solutions that comply with new “soft story” retrofit ordinances in California. These ordinances (part of broad government retrofit mandates) require soft-story structures to be seismically retrofit to better resist earthquake loads.

A soft story structure is typically an apartment complex built over first floor carports with large openings but little structural support to resist the lateral forces of earthquakes.

According to the LA Times, in the City of Los Angeles alone, an estimated 13,500 structures will be subject to the new ordinances. Similar laws have been adopted in the San Francisco and East Bay areas. The Los Angeles and San Francisco building departments are often seen as building safety leaders, and their ordinances are commonly adopted by neighboring jurisdictions.

To bring buildings into compliance with the ordinances, MiTek offers the Hardy Frame® Shear Wall System that includes Prefabricated Panels and Prefabricated Special Moment Frames (SMF), as well as steel connectors from USP Structural Connectors and CIA GEL7000-C epoxy. MiTek has developed a new special soft-story website (link) to showcase its structural retrofit solutions: HardyFrame.com/softstory. (A recent illustrated Journal of Light Construction feature article explains the Hardy Frame SMF installation process, in detail.) “The cost to retrofit is a fraction of the cost to repair or replace a building that’s been damaged in an earthquake. And of course life, personal safety, or even displacement of tenants can’t be measured in terms of cost. The efficient design of MiTek Builder Products retrofit solutions, combined with the simplicity and flexibility of the field installation, will help assure successful retrofits,” said Maged Diab, President of MiTek USA, Inc.

CHESTERFIELD, MO – April 19, 2016 – MiTek® today announced that it has appointed Trace Biles as a Director of National Builders and Supply Chain for MiTek Builder Products. Mr. Biles will focus on sales of MiTek Builder Products’ to large national U.S. home builders. Additionally, Mr. Biles will be a key team member in furthering interaction between MiTek Builder Products and MiTek’s Residential Supply Chain, which supports builders and the supply chain through the SAPPHIRE™ Suite of software solutions. Mr. Biles joins Patrick O’Malley, another Director of National Builders and Supply Chain, who was appointed in the Fall of 2015.

Previous to arriving at MiTek, Mr. Biles was MASCO’s director of national accounts, where he led strategic direction and sales for top-20 national home builders at the corporate, regional, and local levels. Previous to that, Mr. Biles worked at American Woodmark Corp., where he was general manager of the Texas division.

“With his past work with large home builders, Trace brings a highly specialized knowledge to MiTek Builder Products sales efforts,” said Tom Mort, MiTek Builder Products’ Senior VP for Sales and Marketing. “With the very attractive product programs, technical support, and services we have in place for large home builders, we see increasing opportunities to place MiTek Builder Products with them, and we couldn’t be happier to have Trace as part of the team that leads this effort.”

CHESTERFIELD, MO – April 12, 2016 – MiTek® announced today that it has been named “2015 Vendor of the Year” by Carter Lumber.

Carter Lumber is widely regarded among the most-admired companies in the lumber and building materials sector. The Company ranks #13 on the ProSales 100 list of the largest lumber and building material retailers, with 146 locations in 12 states, 3,100 employees, and $1.15 billion in 2015 revenue.

“While a lot has changed in our industry over the last ten years, one thing that has remained constant is the importance of having strong, trusted partners when you go to market. MiTek saw the opportunity in Carter Lumber early on and dived in headfirst, an act that has had a profound and positive impact on both companies. It is because of this unwavering commitment that MiTek was our 2015 Vendor of the Year,” said Jeff Donley, President and COO of Carter Lumber.

“As we continue our growth, we often find ourselves in situations where the status quo doesn’t cut it any longer. As a result, it is important for us to align ourselves with partners like MiTek who can offer us flexibility, resources and the lateral thinking required to keep pace,” added Adam Lombard, Vice President of Product Management for Carter Lumber.

The MiTek relationship with Carter now includes not only the core component manufacturing partnership, but also the offering through its Builder Products division. The products and software now available to Carter include MiTek’s full range of building products and brands assembled after a remarkable series of acquisitions. These product brands include USP® Structural Connectors, the Z4 Tie-Down System, and the Hardy Frame® Shear Wall System.

“Just to count Carter Lumber as one of our customers has been an honor at MiTek. So, the fact that Carter has named us ‘2015 Vendor of the Year’ is all the more humbling. I know I speak for our entire team when I say that we couldn’t be more pleased with this award. Equally important is that we have been entrusted as a key trade partner,” said Tom Mort, MiTek Builder Products’ Senior VP for Sales and Marketing.

About Carter Lumber

Headquartered in Kent, Ohio, Carter Lumber is one of the nation’s largest building materials suppliers. The privately-held, family-owned company was opened in 1932 and now has 146 locations across 12 states in the Midwest, Mid-Atlantic, and Southeast. Learn more: www.CarterLumber.com.

CHESTERFIELD, MO – April 5, 2016 – MiTek® announced today that it has been named U.S. LBM‘s 2015 “Vendor of the Year.”

At most of its locations, reaching across 27 states, U.S. LBM is served by MiTek through its SAPPHIRE™ Structure component design and manufacturing software, MiTek’s manufacturing equipment, as well as MiTek’s MBA™, MVP™, and Shopnet™ software modules. MiTek also provides U.S. LBM with a full line of truss connector plates, and, increasingly, additional products from the MiTek Builder Products division.

“MiTek earned our ‘2015 Vendor of the Year’ award because of their tireless efforts to improve and perfect our component manufacturing operations through superior products, software and support,” said U.S. LBM President and CEO L.T. Gibson. “MiTek has been with U.S. LBM since our inception in 2009, and we couldn’t be happier with their products, services and personnel.”

The award was presented to MiTek at a recent ceremony by L.T. Gibson, U.S. LBM President and CEO; Randy Aardema, U.S. LBM Executive Vice President of Supply Chain; and Rick Kolaczewski, U.S. LBM Chief Financial Officer.

“MiTek’s relationship with U.S. LBM is driven by dedication and excellence in our customer service and technical support, as well as our equipment and software, all of which are second to none,” said Bill Howard, MiTek’s Vice President National Accounts. “We’re honored to have U.S. LBM as a customer, and we will continue to deliver excellence across the full range of our service and product offerings.”

About U.S. LBM

U.S. LBM is a collection of leading building material distributors across North America, with operating locations in 27 states. It is the 3rd largest building products distributor in the United States and recipient of the 2015 ProSales Dealer of the Year award. U.S. LBM implements the philosophy of local management and leadership to capitalize on the premier reputation of its divisions and local customer relationships. Learn more: http://www.USLBM.com.

Fig. 1

CHESTERFIELD, MO – March 29, 2016 – MiTek today announced the release of its new Adjustable Deck Tension Tie (ADTT-TZ), which effectively resists the lateral (horizontal) loads that pull a deck away from the house or structure. The development of the new ADTT-TZ is part of an overall effort by MiTek to make decks safer.

The ADTT-TZ also brings users in compliance with the 2015 International Residential Code R507.2.3(2) which requires the installation of a “Hold-Down Device” with a minimum allowable tension load of 750 lbs., in four locations on the deck. The ADTT-TZ satisfies these requirements.

Fig. 2

The ADTT-TZ’s real innovation is its ability for adjustable installation. Using appropriate fasteners (such as USP WS8-HDG or 3/8-in lag screws), the ADTT-TZ can be installed with the screw either adjacent or up to 4-3/8-in below deck joist, avoiding the need for blocking extensions, see Fig. 1. The ADTT-TZ installed in a “full extension installation” or a “flush installation” is shown below in Fig. 2. Made of 14-gauge steel, with G-185 galvanizing, the ADTT-TZ offers a two-hole break-out washer that will work with multiple screw sizes. Detailed illustrated installation instructions are available at this link.

CHESTERFIELD, MO – March 14, 2016 – MiTek® – a diversified, global business supplying a wide range of engineered products, proprietary design software, and automated equipment sold into the broad construction and industrial end markets – announced today that it has promoted Scott Miller, P.E., to Vice President, Engineering.

Scott Miller has worked at MiTek USA since 1997, and he has been instrumental in the positive evolution of MiTek’s engineering services during his tenure. He started as a design engineer in Chesterfield, MO and then led MiTek’s Edenton, NC office for three years, before returning to Chesterfield as Director of Eastern Engineering Operations. In his new position as Vice President, Engineering, Scott will bring his leadership and expertise to distinguish the engineering division with new levels of excellence.

“In his nearly 20 years at MiTek USA, Scott has achieved a true mastery of the engineering skills that are required to serve our customers with the highest levels of safety and professionalism,” said Steve Cabler, MiTek’s Senior Vice President. “Scott will lead a world-class team of engineers.”

CHESTERFIELD, MO – February 10, 2016 – MiTek today announced that ICC Evaluation Service (ICC-ES), the experts in building product evaluation and certification, has issued ESR-3444 to MiTek’s FWH Fire Wall Hangers, providing evidence they comply with code requirements of the 2012, 2009 and 2006 International Building Codes® (IBC) and International Residential Codes® (IRC). Link to the full ICC press release here: Link.

The FWH Top Mount Firewall Hanger is designed for attaching wood truss, wood I-joist, solid-sawn lumber, or engineered wood lumber floor framing members to either minimum double 2-by 6 nominal wall top plates of wood frame walls or double 2-by solid sawn lumber headers, prior to installation of two layers of 5/8-inch-thick (15.9 mm) gypsum wallboard.

“We are pleased to issue another report to MiTek USA, a manufacturer of innovative building products who continue to rely on ICCES’ technical expertise and high-quality reports, demonstrating proof of code compliance,” said ICC-ES President Shahin Moinian, P.E. “ICCES reports provide code officials with technical information to instantly approve products for installation.”

ICC-ES thoroughly examined MiTek USA’s product information, test reports, calculations, quality control methods and other factors to ensure the product is code-compliant.

“MiTek USA is honored to receive this respected third-party validation of its new FWH Fire Wall Hanger,” said Maged Diab, President for MiTek Builder Products – MiTek USA. “This ICC-ES evaluation report will provide added confidence for specifiers who are looking for a worksaving fire wall hanger solution.”

About ICC-ES

A nonprofit, limited liability company, ICC-ES is the United States’ leading evaluation service for innovative building materials, components and systems. ICCES Evaluation Reports (ESRs), Building Product Listings and PMG Listings provide evidence that products and systems meet requirements of codes and technical standards. The ICC-ES Environmental Programs issue VAR environmental reports that verify a product meets specific sustainability targets defined by today’s codes, standards, green rating systems and ICCES environmental criteria. The Environmental Programs now offer Environmental Product Declarations (EPDs), to meet global market demand for science-based, transparent, quality-assured information about a product’s environmental performance. ICC-ES is a member of the ICC Family of Companies. For more information, please visit www.icc-es.org.

CHESTERFIELD, MO, January 13, 2016 – MiTek® today announced the release of a new product from the MiTek Builder Products division. Focused on creating efficient and optimized wood framing, the new “VTT” Valley Truss Tie is an 18-gauge, G90 galvanized steel tie that transfers loads from a valley truss into the supporting structure below.

The VTT resists the sliding forces created from downward loads when the valley truss is set upon a sloped lower roof. This ability to resist the sliding force eliminates the need for support wedges traditionally used under the valley truss bottom chord. It also eliminates the need for “special order” valley roof trusses that would need to be manufactured with a bevel-cut bottom chord.

The VTT has double-dimple nail holes that assure all nails are driven in at the correct angle into the supporting member every time. It also features a flat design that requires no “field bending” to match the supporting roof pitch.

For ease of installation, the VTT has prong teeth that help hold the VTT in place for nailing. The VTT accommodates supporting roof pitches from 0/12 to 12/12. (Pitch guide embossments allow attachment to valley truss on ground.)

CHESTERFIELD, MO – January 5, 2016 – MiTek Industries, Inc. (“MiTek”), a diversified, global business supplying a wide range of engineered products; proprietary business management and design software; and automated equipment sold into the broad construction and industrial end markets, announced today that it has acquired Sales Simplicity Software, headquartered in Chandler, AZ.

Sales Simplicity Software is the widely acknowledged leader in CRM, sales automation, dynamic content management, and reporting for the home building and real-estate sectors.

“The acquisition of Sales Simplicity Software is yet another step that MiTek is taking to enrich its offering of operations workflow solutions for residential production builders,” stated Tom Manenti, Chairman and CEO of MiTek. “With this acquisition of Sales Simplicity Software, along with our 2015 acquisition of BuilderMT, and previous acquisitions of Simpad and Kova, we offer a truly unique and expansive selection of software for production builders. Sales Simplicity Software has an excellent user-base among production builders and integration into BuilderMT, which MiTek will further strengthen. MiTek will continue to offer solutions and resources to our customers that are second to none.”

“I am so pleased that Sales Simplicity has become part of the MiTek family. I can think of no better long-term home for our company,” said Sales Simplicity’s founder Barry Forbes.

As part of this acquisition, Tom Gebes, the current president of BuilderMT, will also become president of Sales Simplicity and work to tighten the integration between the two companies, as they move toward working together as one system. Customers will still be able to purchase BuilderMT or Sales Simplicity as stand-alone solutions. Sales Simplicity will remain in Chandler, AZ, with no changes to employee base, and Barry Forbes, the founder of Sales Simplicity, will retire in early 2016.

About Sales Simplicity

Sales Simplicity is the creator and marketer of leading sales automation, content management, lead management, eMarketing and reporting management tools for new single-family, semi-custom and custom homes; condo, multi-family, realtor and senior living providers. For more information about Sales Simplicity, call (480) 892-2500 or visit www.SalesSimplicity.net or www.SalesSimplicity.net/SeniorLiving.

2015

CHESTERFIELD, MO – November 11, 2015 – MiTek today announced that it has expanded its Houston, TX warehouse to 50,000 square feet to offer more product variety, more inventory, and fastest order fulfillment rates.

The expanded warehouse will contain USP Structural Connectors, USP Epoxy, MiTek truss plates, and Hardy Frame® Shear Wall product lines. MiTek chose to expand the Houston warehouse to address the needs of local contractor and DIY markets, where MiTek has seen increased demand for its products to address coastal wind codes and general building requirements.

Already operational today, the expanded warehouse will reach its new full capacity in January of 2016, allowing reduced “ship times” and heightened customer responsiveness. In fact, MiTek projects that it will be able to ship most products for same-day or next-day delivery. For even faster responsiveness, the warehouse will also offer local customers the convenience of “will call” capability.

“MiTek has seen growing demand for its products in the Texas markets, and this expanded warehouse will allow us to be much more responsive to order fulfillment for this larger customer base,” said Todd Asche, Senior Vice President of Operations. “The warehouse will feature the latest in inventory monitoring and processing systems, offering the utmost assurance to customers of product availability across our expanded product lines.”

CHESTERFIELD, MO – October 1, 2015 – MiTek today announced that it has launched its new brand of pneumatic, collated gun nails, called MiTek TECO.

The MiTek TECO collated nails have a color-coded and head stamping identification system that identifies the nails’ length and diameter, before and after installation.

This unique color-coding and head-stamping identification system allows a building inspector, or installer, to determine that the right nail has been used when installing MiTek products, without having to remove a nail for inspection. Additionally, engineers who need to ensure that the right nails are used as specified can survey a jobsite and determine proper fastener selections by simply looking at nail colors and head stamps.

The MiTek TECO identification system is simple:

Bright nails. MiTek TECO bright nails feature a color to indicate the nail length and a numeric head stamp to indicate the nail diameter. The color purple indicates a 1-1/2” nail, and the color blue indicates a 2-1/2” nail. For head stamps, a #3 indicates a 0.131 inch diameter, a #4 indicates a 0.148 inch diameter, and a #6 indicates 0.162 inch diameter.

Hot-dip galvanized nails. MiTek TECO hot-dip galvanized nails feature a letter stamp on the head to indicate length (A = 1-1/2” and E = 2-1/2”) along with the numeric head stamp to identify the nail diameter.

Available in “bright,” hot-dip galvanized, or stainless steel, MiTek TECO nails can be installed with the majority of the popular 33-degree paper tape pneumatic nail guns (plus or minus 2 degrees). MiTek TECO nails are manufactured in lengths of 1½ or 2½ inches, in diameters of 0.131”, 0.148”, and 0.168”.

MiTek TECO nails are certified by ASTM F1667 (ASTM A153), and have been evaluated by ICC-ESR 3768 – 2015 & 2012 IRC/IBC.

MiTek Builder Products division will sell and represent the product nationally.

“MiTek TECO nails allow for easier, more accurate, fastener selection for framers, so they always get the right nail the first time,” said Brent Kreutzer, MiTek TECO brand manager. “Now, with MiTek TECO, we offer a dramatic improvement in the way that nails are identified in the field, lessening the chance for error and making the inspection process easier.”

CHESTERFIELD, MO – September 16, 2015 – MiTek® Industries, a Berkshire Hathaway company, today announced that its SAPPHIRE Supply software solution is gaining strong reception, evaluation and adoption among leading lumber and building material dealers.

Designed specifically to meet the needs of lumber and building material dealers, SAPPHIRE Supply is a single-source software solution that uniquely combines complete materials estimating and structural frame design. SAPPHIRE Supply also incorporates the building material supplier’s product SKU’s to create a complete quote, while performing analysis and design on a wide range of structural products including leading proprietary engineered wood products (EWP), dimensional lumber, and metal connectors and hangers.

Since SAPPHIRE Supply is part of the SAPPHIRE Suite, SAPPHIRE Supply allows dealers who are suppliers of USP Structural Connectors and their MiTek component manufacturers to collaborate by sharing common Building Information Models (BIM), all of which can be viewed on MiTek’s free SAPPHIRE Viewer software.

SAPPHIRE Supply uses a single shared structural model, offering lumber dealers a unified solution for efficient, consistent and accurate modeling and estimating across their organizations. SAPPHIRE Supply approach eliminates the classic problem of inconsistent sales estimating within an organization, delivering accurate modeling and estimating on every home.

Since SAPPHIRE Supply is based on the geometry of a structural model, the software can also generate SKU-based materials counts for non-structural materials, such as drywall, house wrap and even millwork. SAPPHIRE Supply‘s flexible formula-builder, coupled with the power to define accumulation rules, results in accurate material counts to match how materials are actually supplied. Verifiable bills of materials (BOMs) can be generated with exacting precision and are visually tracked within the 3D structural model.