Features

Save Labor.

Minimize Injuries.

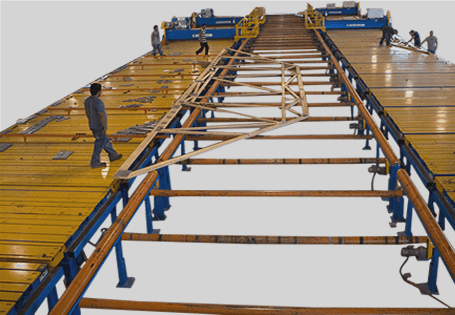

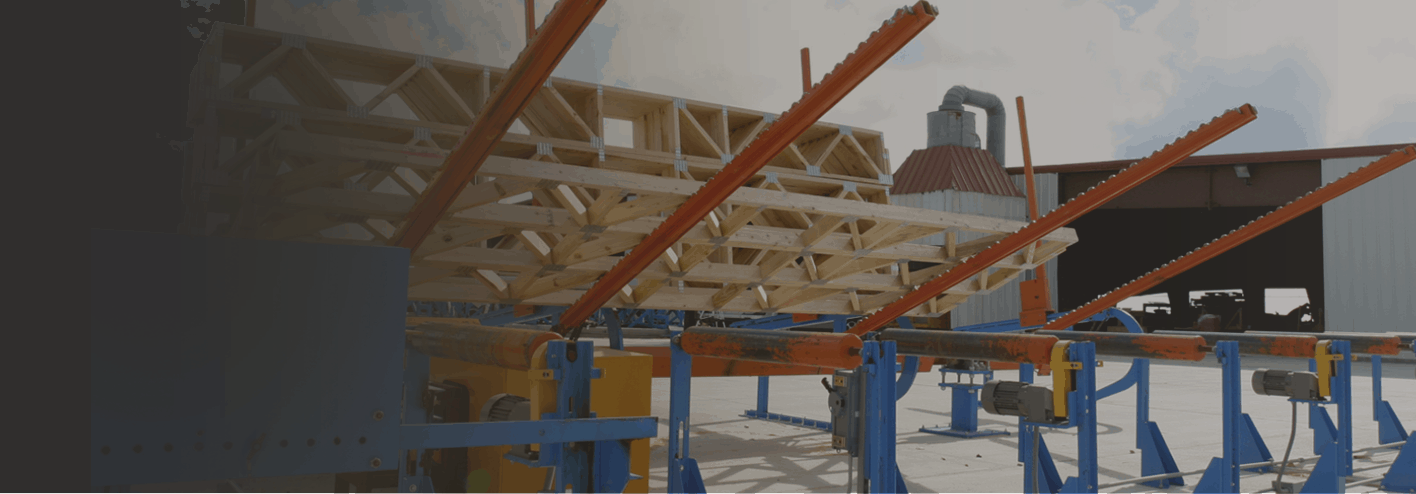

- When placed outside, valuable in-plant space is saved.

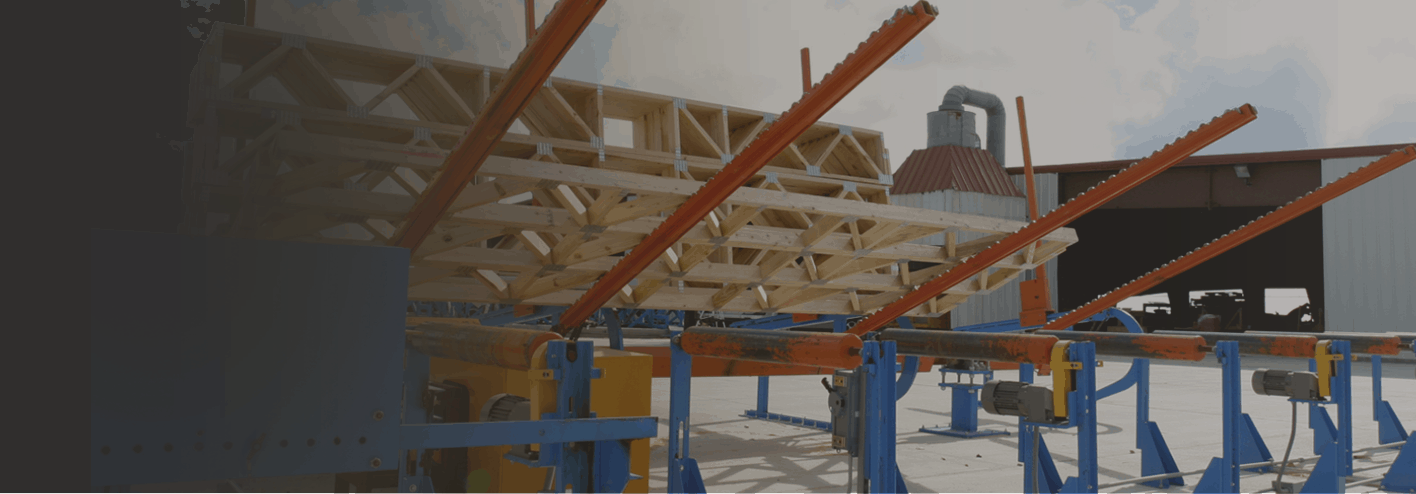

- Stacks floor trusses onto the receiving stands one, two, or three high.

- Lifts the trusses to an elevated position and allows them to roll down the stacker arms to a fixed stop.

- Places the trusses onto the receiver stands when the required quantity of trusses are in position.

Floor Truss Tracker Overview Video

Specifications

OVERVIEW

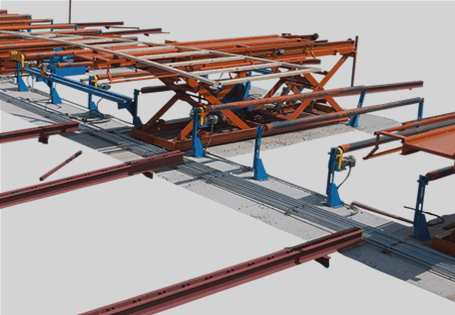

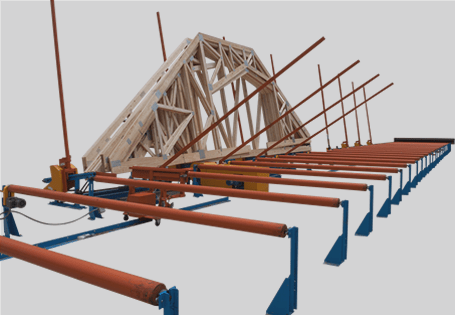

The system offers the capability of stacking floor trusses onto the receiving stands one, two, or three high. The stacker lifts the trusses to an elevated position and allows them to roll down the stacker arms to a fixed stop. When the required quantity of trusses are in position, the stacker will lift the trusses onto the receiver stands.

The Floor Truss Stacker can come equipped with powered conveyors. These increase productivity while decreasing labor costs.

- Receiver stand has a 1200 lb. capacity and can automatically index for the next truss or stack of trusses.

- Cycle time is 40 seconds and the machine can stack trusses from 10′ to 40′ in length.

- Stacks can grow from 3-1/2″ to 48″ in width (depth).

The Floor Truss Stacker is most effective when paired with MiTek’s Powered Stand-Alone Conveyor, excellent at increasing productivity while reducing labor costs.

PHYSICAL DATA

| Components | Stacker and receiver stands |

| Stacker Dimensions | 23′ x 15′ |

| Motor | 2 hp |

| Approx. Weight | 13,000 lb |

PERFORMANCE DATA

| Modes | Auto or Manual |

| Cycle Time | 40 seconds |

| Weight Capacity | 1,200 lb per zone |

| Truss Length | 10′ to 40′ |

| Min. Truss Width | 9′ 1/4″ |

| Max. Truss Width | 24″ if stacking three high |

| Stack Height | 1, 2, or 3 trusses on edge |

| HMI | Pushbutton Station |

ELECTRICAL DATA

| Electrical Specs | 208/230/460 VAC, 3-phase, 60 Hz |

SAFETY DATA

| Pushbuttons | Pushbuttons |

| Safety Compliance | UL (panels), OSHA |

| Labels | Bilingual or ISO |

Download the Full Spec Sheet

Download PDFAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.