KB Home

Off-Site Design and Framing Methods Lead to Cycle-Time Reductions for KB Home ProjeKt.

HIGHLY ACCELERATED CONSTRUCTION PACE WHEN MOVING FROM “DIRT TO DRY-IN”

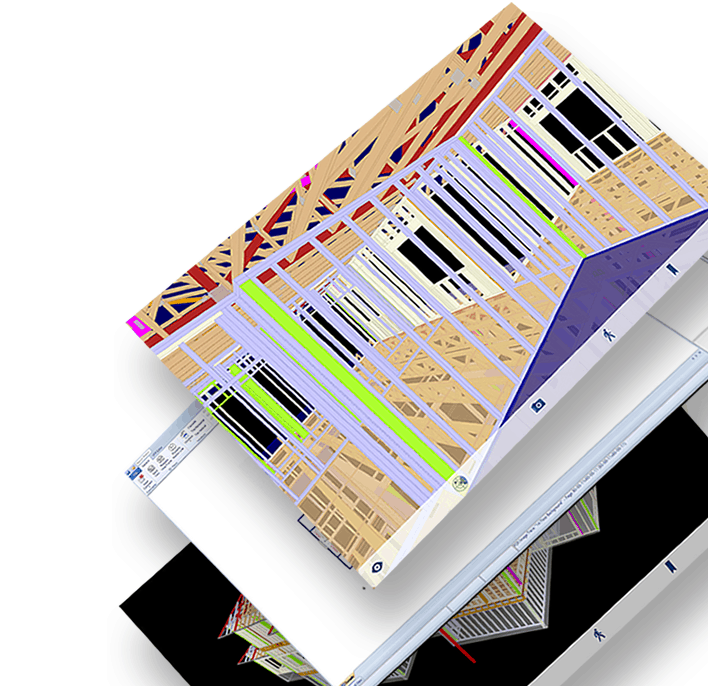

Shorter framing cycle times for the KB Home ProjeKt were realized through collaboration enabled in part by MiTek Kova 3D BIM structural modeling software and MiTek automated equipment.

The Story

HEALTHIER, SUSTAINABLE HOUSING

HOME IS WHERE TOMORROW LIVES

The KB Home ProjeKt was aided by 3D BIM structural framing software and automated manufacturing to integrate the off-site process from design all the way through to the manufacturing and final jobsite assembly of the framing.

Off-site design and framing methods like this, coupled with the cycle-time reduction they create, are key to solving the continuing framing labor shortage and the lack of new housing.”

INNOVATION

The BUILDER KB Home ProjeKt is an innovative collaboration that combines architecture, technology and science to help homeowners improve their physical and emotional health and well-being. The off-site construction framing process of this model home incorporates 3D-modeled and advanced panelized framing. Using a highly collaborative approach, the design and construction accounts for all the framing details, as well as the MEP placement and HVAC optimization in the building process.

HEALTHY BY DESIGN

According to the CDC, the conditions in the places that we live, learn, work and play are the single greatest factor in our health. Today’s technological advancements are helping make smart homes a reality in order to help homeowners improve their physical and emotional health and well-being. Off-site design and framing methods leading to cycle-time reductions that are key to solving the continuing framing labor shortage and the lack of new housing.

PARTNERING WITH KB HOME

MITEK INTEGRATION

MiTek’s Kova Portal provided a central digital repository to track and maintain version control of documents and plans for the KB Home ProjeKt. Truss and panel design and manufacturing were enabled by MiTek’s design and process-management software solutions, which also drive MiTek’s automated equipment to create the final structural components. MiTek’s Lateral Systems and MiTek Structural Connectors are featured as well, along with MiTek Wrightsoft® Production Home Design Service Group for the optimized HVAC system design to optimize the home’s comfort, efficiency, and indoor air quality. MiTek’s structural BIM model of the home was also central to Wrightsoft’s design for the highly efficient system and its layout.

Visit KB Home to learn more.