ICC CODE COUNTS ARTICLE

ICC CODE COUNTS ARTICLE: DECEMBER 2017

PROPER USE OF FASTENERS

HOW ENGINEERS AND ARCHITECTS CAN HELP ENSURE FASTENERS MEET CODE IN STEEL STRUCTURAL CONNECTORS USED WITH WOOD CONSTRUCTION.

By: Todd Grevious P.E. at MiTek USA, Inc.

When architects and engineers specify nail and screw fasteners for steel structural connectors used with wood construction, there’s an assumption that the contractors, who are installing the connectors, understand the differences between the different types of nails and fasteners out there on the market and what fastener they should be using for the installation. But that assumption may lead to confusion on the part of builders – and the wrong type of fastener being used in connectors.

Why does this matter? The answer is structurally rated products such as connectors and joist hangers evaluated for use under the International Building Code® (IBC) require a specific type of fastener to achieve their allowable design values. When wood framing members are connected using structural connectors with evaluation reports in accordance with 2009, 2012, and 2015 IBC sections 2304.10 or Section R301.1.3 of the IRC, fastener type is critical to the performance of the connectors.

For example, a typical slant nail joist hanger requires the installation of full length common nails for a proper hanger installation. Often times installers will use shorter nails commonly referred to as “joist hanger” nails. These nails are a shorter length of 1-1/2” and will reduce the allowable design capacity the hanger will support.

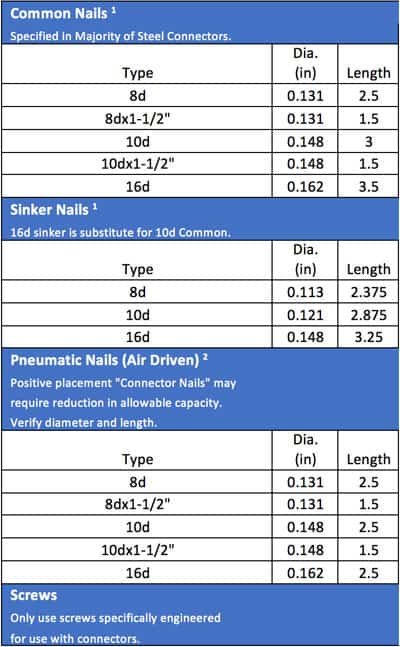

If the right fasteners aren’t used, the allowable design values no longer apply. Calling nails as a generic term like 10d is a good example of this problem in action. Many hangers are supposed to use 10d common nails as fasteners, according to the ICC-ES product evaluation reports. But does the installer take the time to learn what 10d common nails really are? A 10d common nail is 0.148 inches in diameter and 3 inches in length in nominal dimensions. But 10d nails also come in sinker, pneumatic, and even box types, all of which have different measurements

In other words, the 10d nail specified is not always the 10d nail the installer uses or that the ICC-ES evaluation report and subsequently the code demands. Many builders aren’t aware of the nuance involved in such nomenclature. They may think a 10d nail is a 10d nail.

Are these types of problems leading to unsafe buildings? Fortunately, because wood is a nonhomogeneous material, there are a lot of factors of safety built into wood construction. Most wood buildings have repetitive and redundant members, and furthermore, most connectors are designed to support loads that far exceed the service loads that will be placed on them.

However, this does not mean the industry should not take more steps to clear this up. Using the wrong fastener can lead to more deflection and movement in the structure. This movement may manifest as squeaky that can become a serviceability problem. In the case of transient loaded connectors like hold-downs and hurricane ties, the wrong fastener can lead to increased deflection at demand load and further damage in a wind or seismic event.

Thus, it’s incumbent on engineers and architects to clearly specify the proper fasteners in a more precise way installers can understand. The clearest and simplest way to accomplish this goal is to specify fasteners using diameter and length rather than a fastener name which can lead to confusion. However, if only the fastener name is called out in a table, make sure that the length and diameter of the fasteners are clearly referenced in the table. The table in this article is a good place for architects to educate themselves on these specifications. The table contains length and diameter information on most of the fasteners used in steel structural connectors. Refer to the National Design Specification for Wood Construction (NDS) or ICC-ES ESR-3768 for a more complete listing of fastener types used in wood construction.

By ensuring the proper use of fasteners in structural connectors, architects and builders alike can be assured that their structures are being built to the proper code and will be more likely to stand the test of time.

Finally, non-structural nails, such as nails for components and cladding, should NEVER be used in structural connectors. Screws should ONLY be used if specifically engineered to be used with structural connectors.

1. Information obtained from 2015 National Design Specification (NDS) for wood Construction.

2. Diameter and length information obtained from ICC-ES ESR-3768. Pennyweight naming conventions and available lengths vary between manufacturers.

{Disclosure statement}

The views and opinions expressed in this article are those of MiTek USA, Inc. and do not necessarily reflect those of the International Code Council, or Hanley Wood.