Plated Truss

Skewed Nail Plate

SNP

Reference Series: TJC

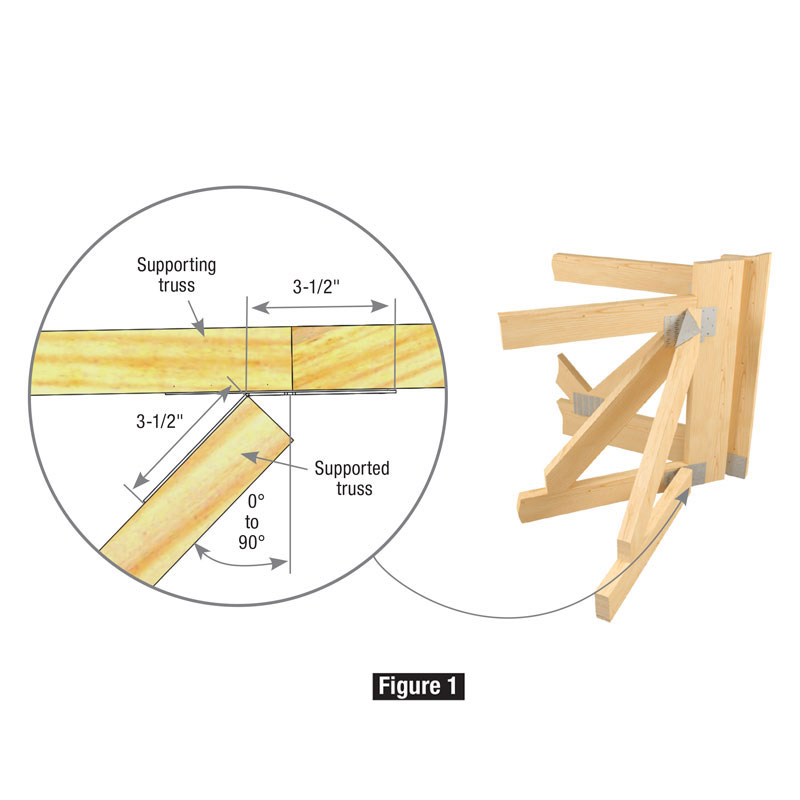

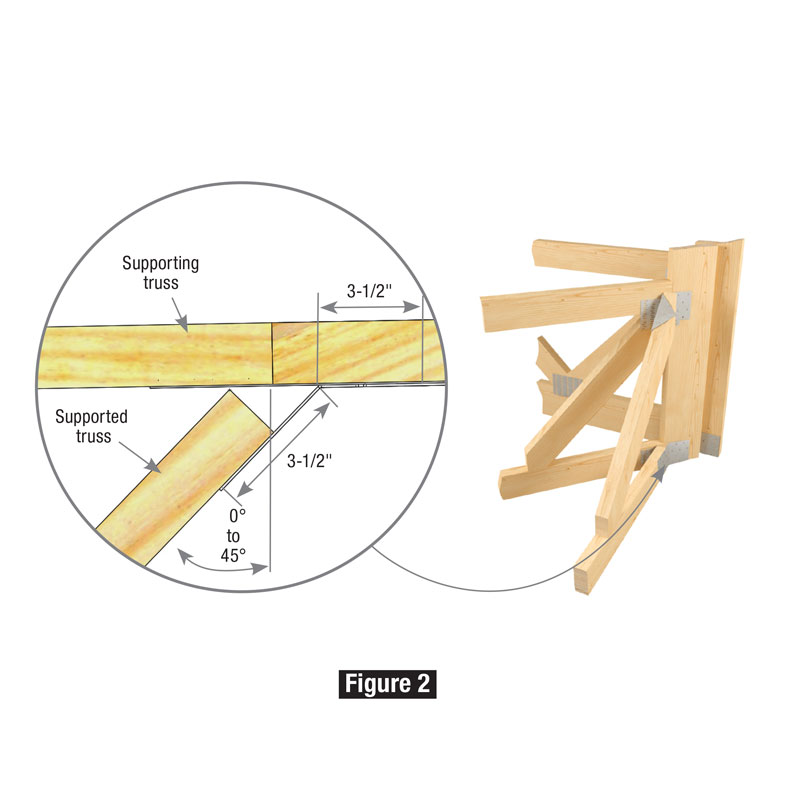

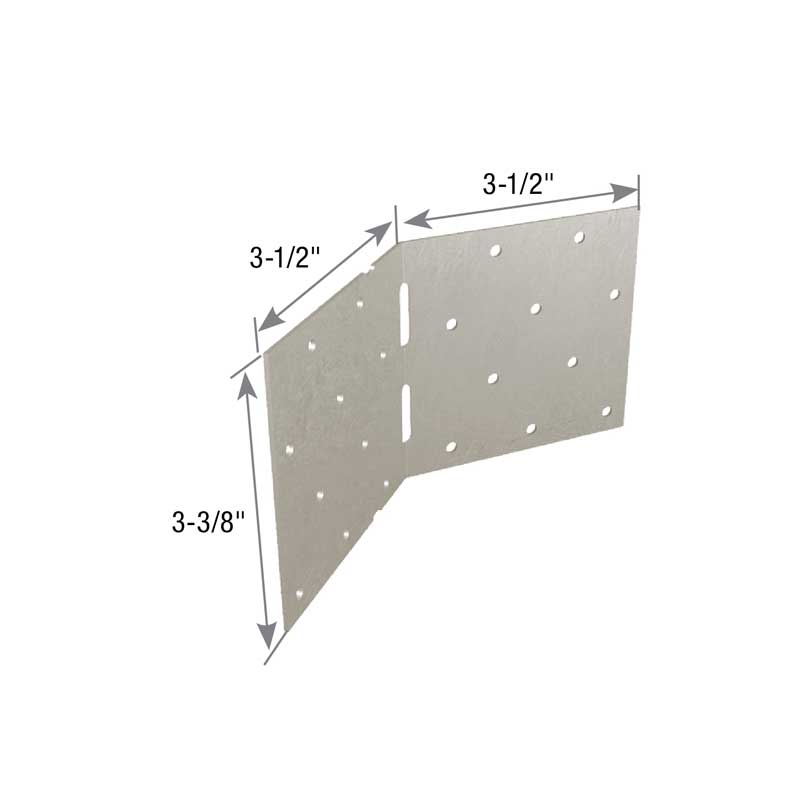

The SNP3 Skewed Nail Plate is designed for connecting square cut corner jack trusses at skews from 0° to 90°. An alternate installation for skews from 0° to 45° is depicted in Figure 2.

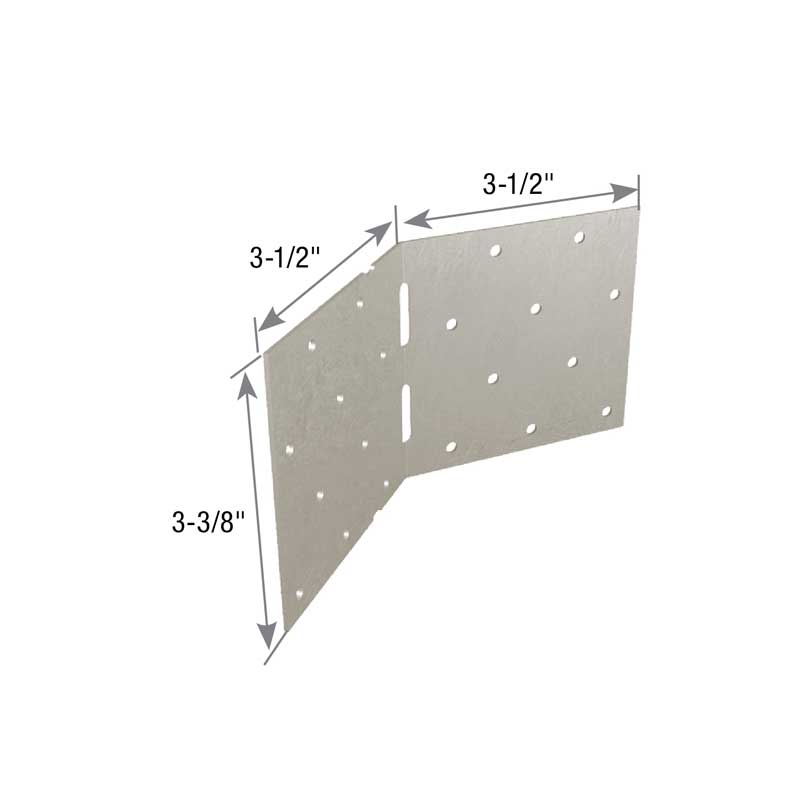

Materials: 16 gauge

Finish: G90 galvanizing

Code Reports:

View Code Report Table

Technical Bulletins

Installation

Bend angle only once.

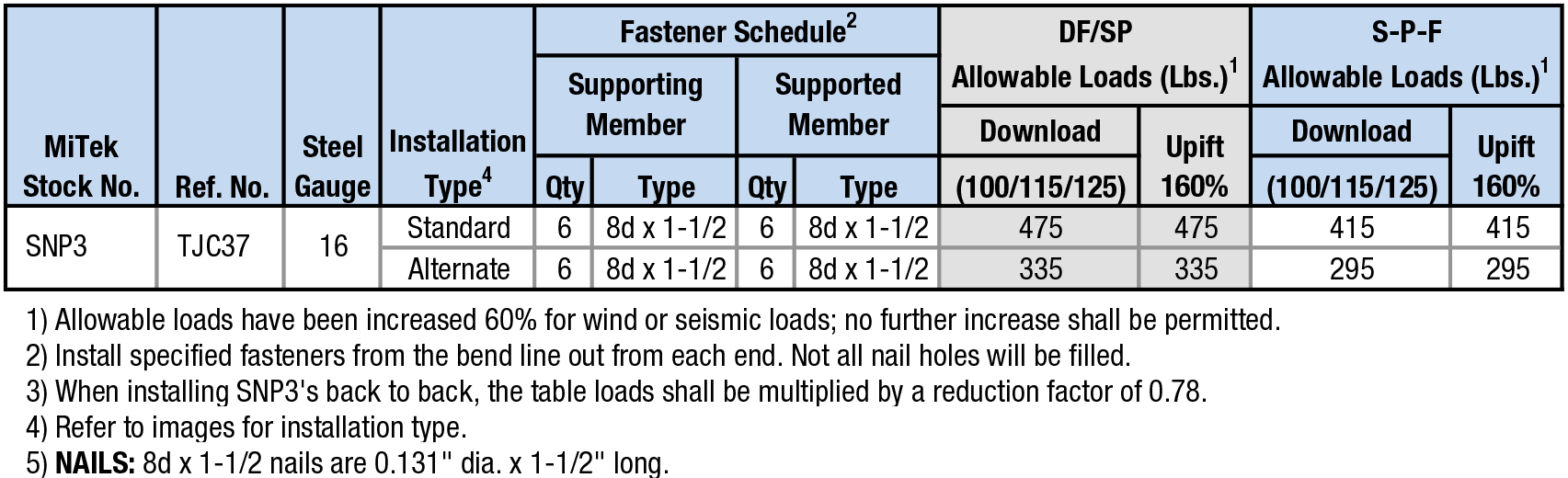

- 8d common (0.131″ dia. x 2-1/2″ long) nails may be substituted for 8d (0.131″) x 1-1/2″ nails with no reduction in load.

Typical Installation (Figure 1):

- Attach the SNP3 to the supported truss on the acute angle side so the SNP3 runs behind the end of the jack truss. Use all the specified fasteners listed in the table below. The fasteners should be installed nearest to bend line as possible then working to the opposite end of flange. Not all nail holes will be filled.

- Set the jack truss against the supporting truss and nail the exposed flange of the SNP3 into place. Use all the specified fasteners listed in the table below. The fasteners should be installed nearest to bend line as possible then working to the opposite end of flange. Not all nail holes will be filled.

Alternate Installation (Figure 2):

- Attach the SNP3 to the supported truss on the obtuse angle side so the SNP3 is on the front side of the jack truss. Use all the specified fasteners listed in the table below. The fasteners should be installed nearest to bend line as possible then working to the opposite end of flange but no closer than 5/8” from the end of the truss. Not all nail holes will be filled.

- Set the jack truss against the supporting truss and nail the exposed flange of the SNP3 into place. Use all the specified fasteners listed in the table below. The fasteners should be installed nearest to bend line as possible then working to the opposite end of flange. Not all nail holes will be filled.

Need Help or Have a Question? Contact Customer Service or Call 800-328-5934

SNP3 Skewed Nail Plate