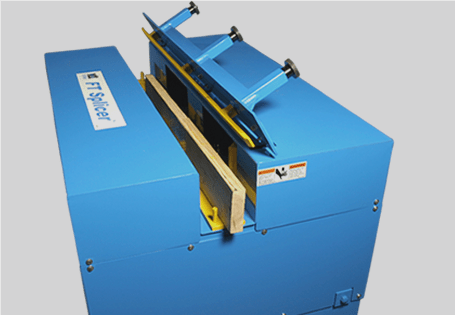

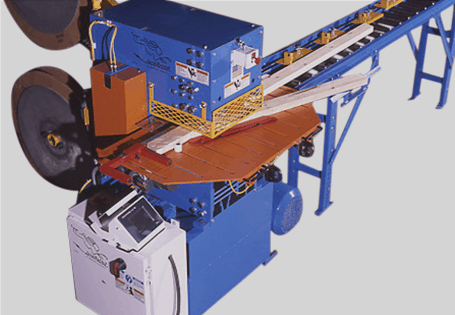

RoofTracker III™

The latest evolution of the long-running RoofTracker series of roller presses.

Features

SINGLE-PASS PRESSING OF TOP AND BOTTOM PLATES

- Powerful 15-hp motor is capable of pressing large plates.

- Operates with joystick mounted to a simple control station.

- Scanners on each side of the press head keep employees safe while also preventing equipment damage.

- Integrates with RoofGlider®, RoofTracker™, or AutoPress™ gantry heads.

- Works with Virtek® laser projection system to eliminate tape measuring.

- Travels up to 165 feet per minute.

RoofTracker III Overview Video

SPECIFICATIONS

The RoofTracker ™ III is a high-powered roller press that presses the top and bottom plates in a single pass. The gantry head fits on any MiTek roof truss assembly table and is perfectly suited to work with MatchPoint® Wizard PDS™ automated jigging.

This truss assembly machine now has a larger motor for pressing larger plates. Enhanced safety features include a scanner on each side of the gantry head to detect obstructions and keep employees safe.

PHYSICAL DATA

| Length of Gantry Throat | 12’6″ or 14′ or 16′ |

| Roller Size | 24″ (nominal OD) |

| Roller Material | 1″ steel |

| Roller Height Adjustment | 4-1/2″ of adjustment |

| Motor | 15 hp |

| Integration With Other Presses | Integrates with any RoofGlider or RoofTracker series gantry head. |

PERFORMANCE DATA

| Speed of Gantry | up to 165 FPM |

| Plate Embedment | 50-80% (Finish Roller required) |

| Direction of Travel | Left/right |

| HMI | Joystick and pushbutton control station. |

Electrical Specifications

| Voltages | 208v, 230v, 415v, 460v, 575v |

| Uses overhead bus bar or festoon cable |

| E-stops | Pushbutton |

| Safety Compliance | UL (panels), OSHA |

| Indicators of Movement | Horn and beacon light |

| Labels | Bilingual or ISO |

- Roller lengths (throat opening): 12′ 6”, 14′, or 16′

- Multi-press head interlock (can interlock with any RoofGlider®, RoofTracker™, or AutoPress™ head)

- Powered stand-alone conveyors and transfer rollers

- Operator platform on bottom chord or top chord end

- See the Tables page for these options:

- End-eject or auto-eject systems in tables

- Virtek® laser projection system

- MatchPoint Wizard PDS automated jigging

MatchPoint® PDS Tables – Tables for MiTek® roller presses that easily accept Wizard PDS™ automated jigging.

Download the Full Spec Sheet

Download PDFAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

Machinery Equipment

View more of the most complete, reliable, and productive component manufacturing equipment in the industry.