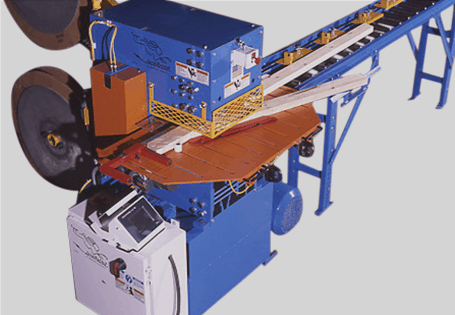

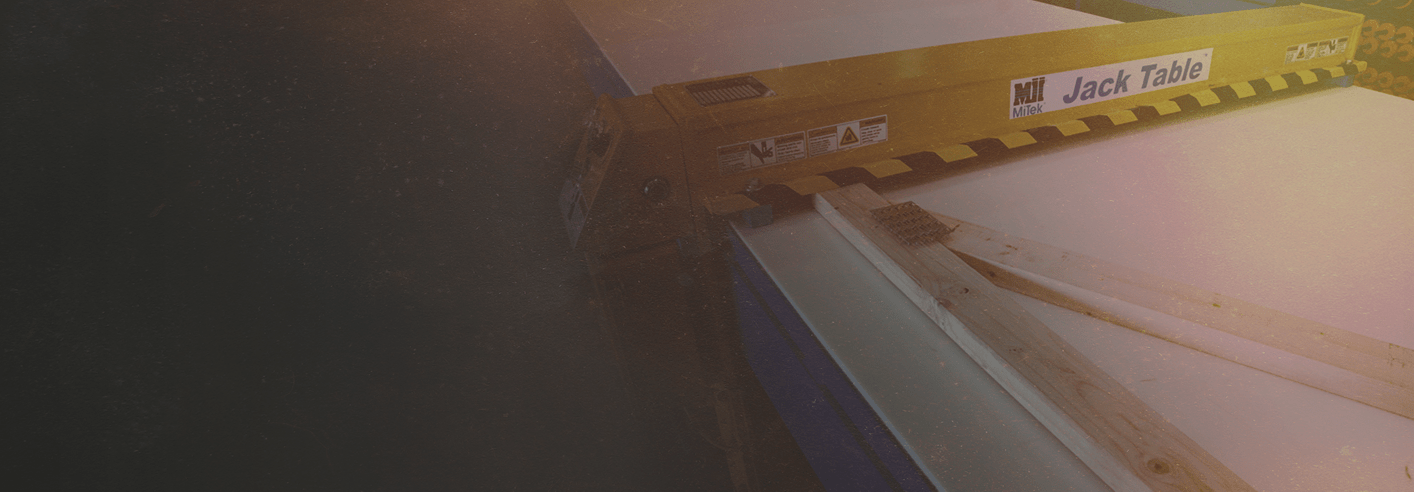

Jack Table™

Platen Press

Complement your larger lines with this flexibile and speedy platen press.

Features

FLEXIBILITY

AND SPEED

- Raise the pressing force from 30 tons to 50 tons of pressure with the turn of a switch.

- Many different options for jigging, table length, and table-top material.

Jack Table Platen Press Overview Video

Specifications

OVERVIEW

This platen press is designed specifically for jack trusses, but its flexibility, speed, and power can complement your larger lines in many ways.

- Installs within hours and an operator can be proficient within minutes, allowing you to ship jack trusses out the door on the same day the machine is delivered.

- Uses U-channels and U-channel jigging.

- Horizontal travel driven by hydraulic motor.

PHYSICAL DATA

| Components | Gantry head and single table |

| Dimensions of Table | Choice of 20′, 24′, 30′ length x 6′ wide |

| Platen Working Surface | 66′ 1/2″ x 12″ |

| Platen Material | 1″ thick steel |

| Table-top Material | 1″ solid plastic on top of 3/4″ plywood (see Options) |

| Throat Opening | Adjustable up to 4-3/4″ |

| Hydraulic System Motor for Pressing | 7-1/2 hp |

| Hydraulic Reservoir | 7 gal. |

PERFORMANCE DATA

| Pressing Capacity | 50-ton |

| Lumber Capacity | Any lumber up to 4-1/2″ thick, and less than 12″ wide |

| Max. Truss Height | 5′ 6″ |

| Max. Truss Length | Length of table |

| Plate Embedment | 100% |

| Direction of Travel | Left and right |

| HMI | 2-position joystick and dual (2-handed) pushbuttons |

ELECTRICAL DATA

| Electrical Specs | 208/230/460/575 VAC, 60 Hz 3-phase 380/415 VAC, 50 Hz 3-phase |

| Uses overhead bus bar or festoon cable |

SAFETY DATA

| Controls | 2-handed operating control buttons |

| E-stops | Pushbutton |

| Safety Compliance | UL (panels), OSHA |

| Indicators of Movement | Horn and beacon light |

| Labels | Bilingual or ISO |

OPTIONS

- Heater for hydraulic fluid (recommended in cold environments)

- Platen blocking for 3x and 4x dimensional lumber

Download the Full Spec Sheet

Download PDFAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.