Timber Technologies

Two companies collaborate on a build using 3D BIM modeling for wall panel design, with the result of no errors and a new standard of “precision down to the nailhead.”

ONSITE FRAMING TIME CUT IN HALF

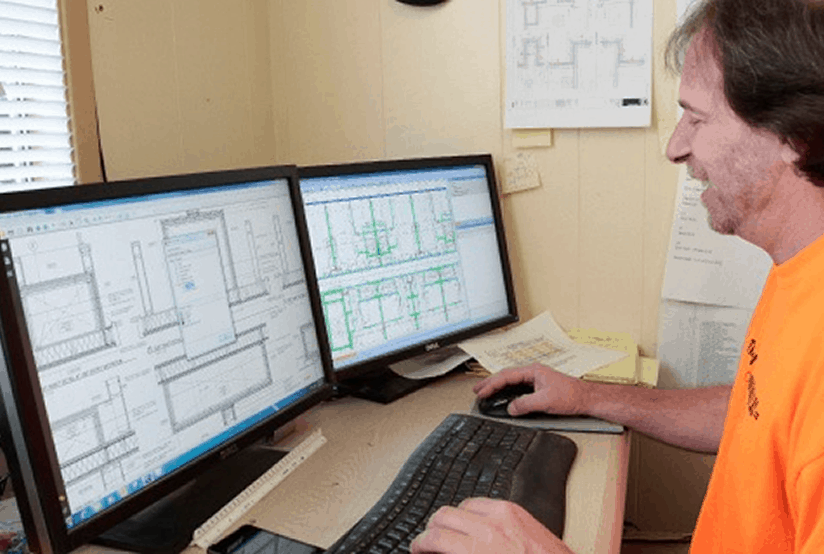

“With wall panel design and truss design both being handled in SAPPHIRE®, we can cut onsite framing time in half,” designer, Ken Pappadis said. The result? Error-free, code-compliant optimized wood frames, put up in just over half the time as a similar structure that is stick framed onsite.

The Story

COLLABORATION

COLLABORATE DURING THE DESIGN

Their objective? Create an error-free, code-compliant wood frame. Their solution: collaborate during the design and construction phases to avoid misalignments and errors.

With…SAPPHIRE, we can cut onsite framing time in half.”

THE BACKGROUND

Timber Technologies, a wall panel designer and framing contractor, and Precision Truss & Lumber, who produce roof and floor trusses, designed a 141,753-square-foot wood-framed building. The objective: create an error-free, code-compliant optimized wood frame. To avoid mis-alignments and errors, they collaborated during the design and construction phases.

CHALLENGE

If one company does the walls (Timber Technologies) and another company does the floor and roof trusses (Precision Truss & Lumber), what ties them together? How can they possibly collaborate effectively?

THE SOLUTION

3D BIM MODELING

Crossed wires and costly errors were avoided by collaborating on a single SAPPHIRE® model. Floor trusses and roof trusses were digitally overlaid on the wall model and worked out in the digital design. 3D BIM modeling allowed Timber Technologies and Precision Truss and Lumber to stop clashes, misalignments, and errors before they began, and minimize onsite framing time.