FEATURES

TACKLE THE

TOUGHEST JOBS

- Safety features on every machine, including a scanner and operator platform.

- Standard electrical control designs which include a fully integrated safety circuit with safety modules and redundant contacts for operator safety.

- Multiple sensors and gauges to monitor the machine and assist with maintenance.

AutoPress 14TL Overview Video

SPECIFICATIONS

OVERVIEW

- Sensors monitor cleanliness of hydraulic fluid filter, level of fluid, and temperature of fluid.

- Automatic temperature control keeps the hydraulic fluid at optimum temperature.

- Hydraulic system has idle time for automatic shutoff when not in use.

- Display screen communicates system status and faults.

- Operator platform and two joysticks offer full visibility of the pressing surface.

- Easily integrates with MiTek RoofTracker™ and RoofGlider® gantry heads.

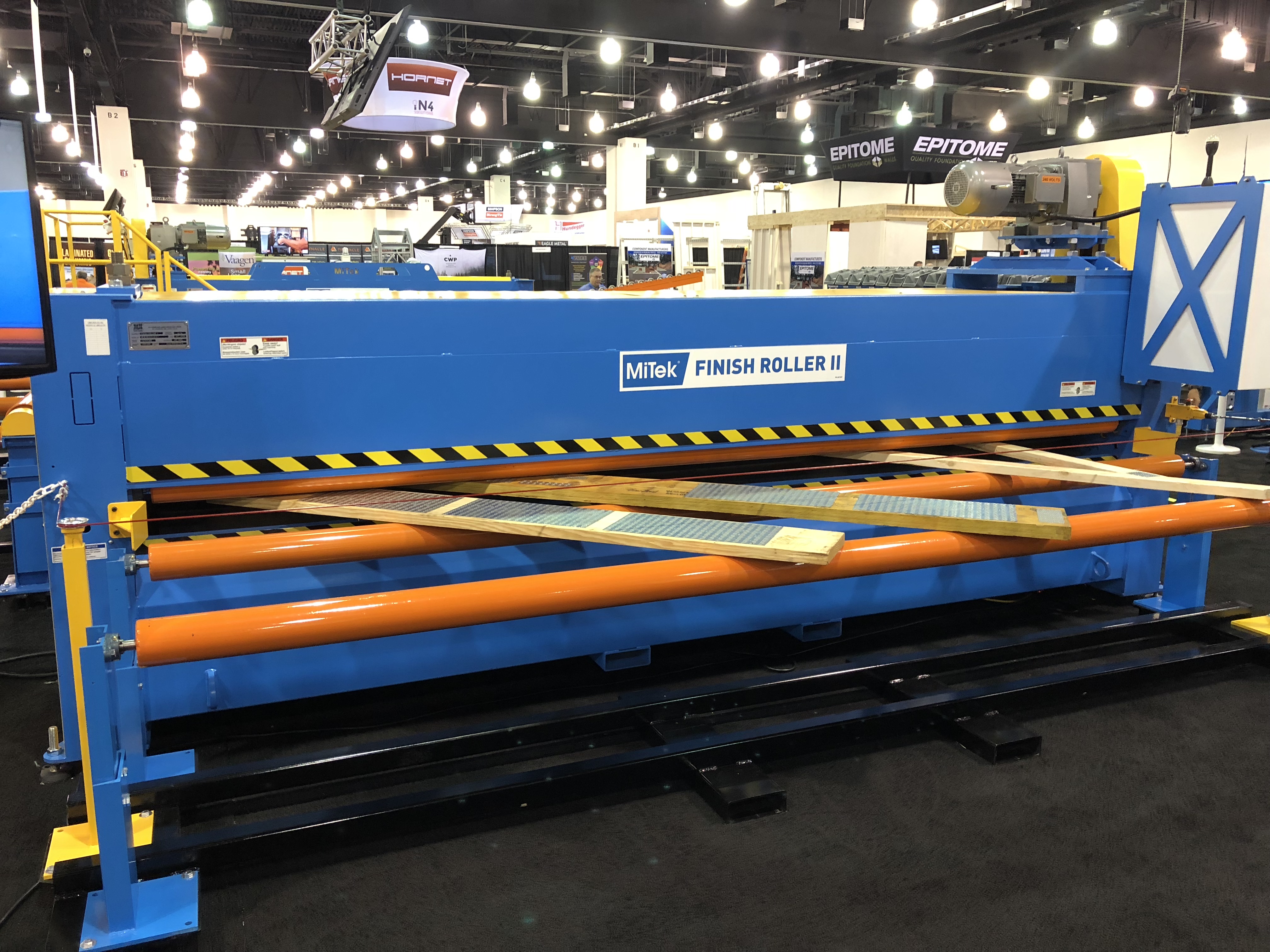

- 50 tons of pressing force ensure good plate embedment while a Finish Roller cleanly completes the job.

PHYSICAL DATA

| Components | Gantry head, tables, and parking stands |

| Platen Size, Material, and Opening | 16′ 6-3/4″ long x 30″ wide 1-1/2″ thick steel Vertical: 3/4″ to 5-3/4″ up from table surface (adjustable) Camber on Platen: 1/16″ max. down at midpoint |

| Wheels | 8 drive wheels (10″ diameter), 8 guide wheels (5″ diameter) |

| Hydraulic System Motor | 20 hp |

| Drive System Brake Motor | 10 hp |

| Hydraulic Reservoir | 90 gal. |

| Table Working Surface | 13′ 11-1/2″ x 6′ 1-3/4″ with 3/4″ steel table top |

| Integration with Other Presses | Integrates w/RoofTracker™ and RoofGlider® Stand-alone system or can be integrated with RoofTracker or RoofGlider system. RoofTracker and RoofGlider head can travel and press on AutoPress 14TL tables. AutoPress 14TL head can travel on RoofTracker and RoofGlider tables, but can only press on AutoPress 14TL tables. |

PERFORMANCE DATA

| Pressure Modes | High or Low |

| Pressing Capacity | Max. of 50 tons in High Mode |

| Speed of Travel | Up to 125 FPM |

| Lumber Capacity | Max. 5-1/2″ thick by 13′ 11″ long |

| HMI | 4-position joysticks (2) and pushbuttons |

| Plate Embedment | 60%-90%, Finish Roller required |

ELECTRICAL DATA

| Electrical Specs | 208/230/460/575 VAC, 3-phase, 60 Hz |

| Overhead bus bar system required |

SAFETY DATA

| E-stops | Pushbutton, light bars, 6 bumpers |

| Additional Stop Methods | Bumpers on gantry head |

| Interlocks | For use with multiple press head option |

| Safety Compliance | UL (panels), OSHA |

| Indicators of Movement | Horn and beacon light |

| Labels | Bilingual or ISO |

OPTIONS

- Multiple press heads w/interlock

- Aisle covers for continuous-top system

- Virtek® laser projection system

- Powered Stand-alone Conveyors

- Table ejection options available (must match existing system if integrating): Side-eject, auto-eject

DOWNLOAD THE FULL SPEC SHEET

Download LinkAutomation SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

RELATED EQUIPMENT

View more of the most complete, reliable, and productive truss assembly manufacturing equipment in the industry.